Asean B shaft length is a crucial factor to consider when choosing the right industrial component for a specific application. But what exactly does it refer to, and why is it so important? This comprehensive guide delves into the intricacies of Asean B shaft lengths, providing valuable insights for engineers, technicians, and anyone seeking a deeper understanding of this critical aspect of industrial equipment.

What is Asean B Shaft Length?

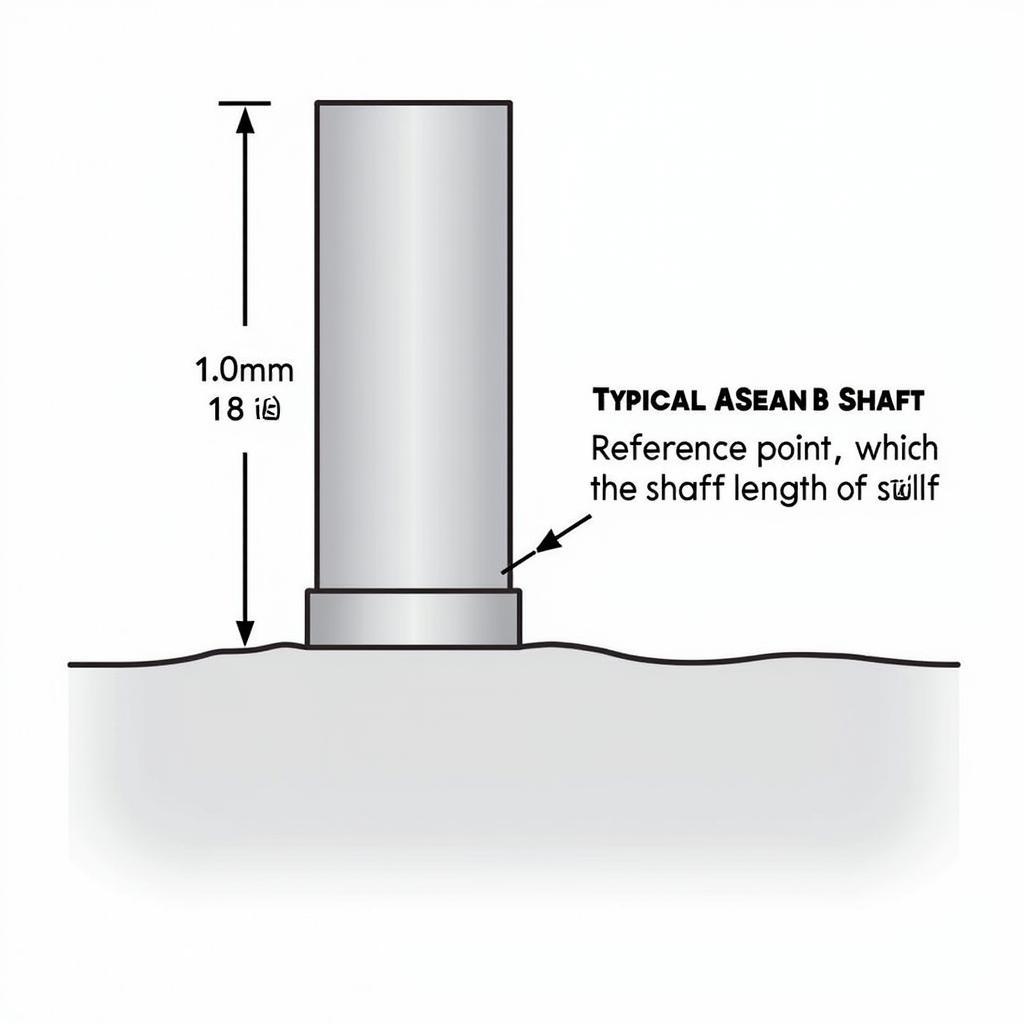

Asean B shaft length refers to the measurable distance from the end of a shaft to a designated reference point, typically the mounting surface or shoulder. This measurement is standardized within the ASEAN region to ensure compatibility and interchangeability of components across different manufacturers and applications.

Measurement points on an Asean B shaft

Measurement points on an Asean B shaft

Why is Asean B Shaft Length Important?

The significance of Asean B shaft length becomes evident when considering its impact on the overall functionality and performance of industrial equipment. Here’s why it matters:

- Compatibility: Standardized shaft lengths ensure seamless integration of components from different manufacturers, promoting flexibility and cost-effectiveness in equipment design and maintenance.

- Performance: Selecting the correct shaft length is crucial for optimal power transmission, alignment, and overall efficiency of the machinery.

- Safety: Deviations from standard shaft lengths can lead to misalignment, vibrations, and premature wear and tear, potentially resulting in equipment failure and safety hazards.

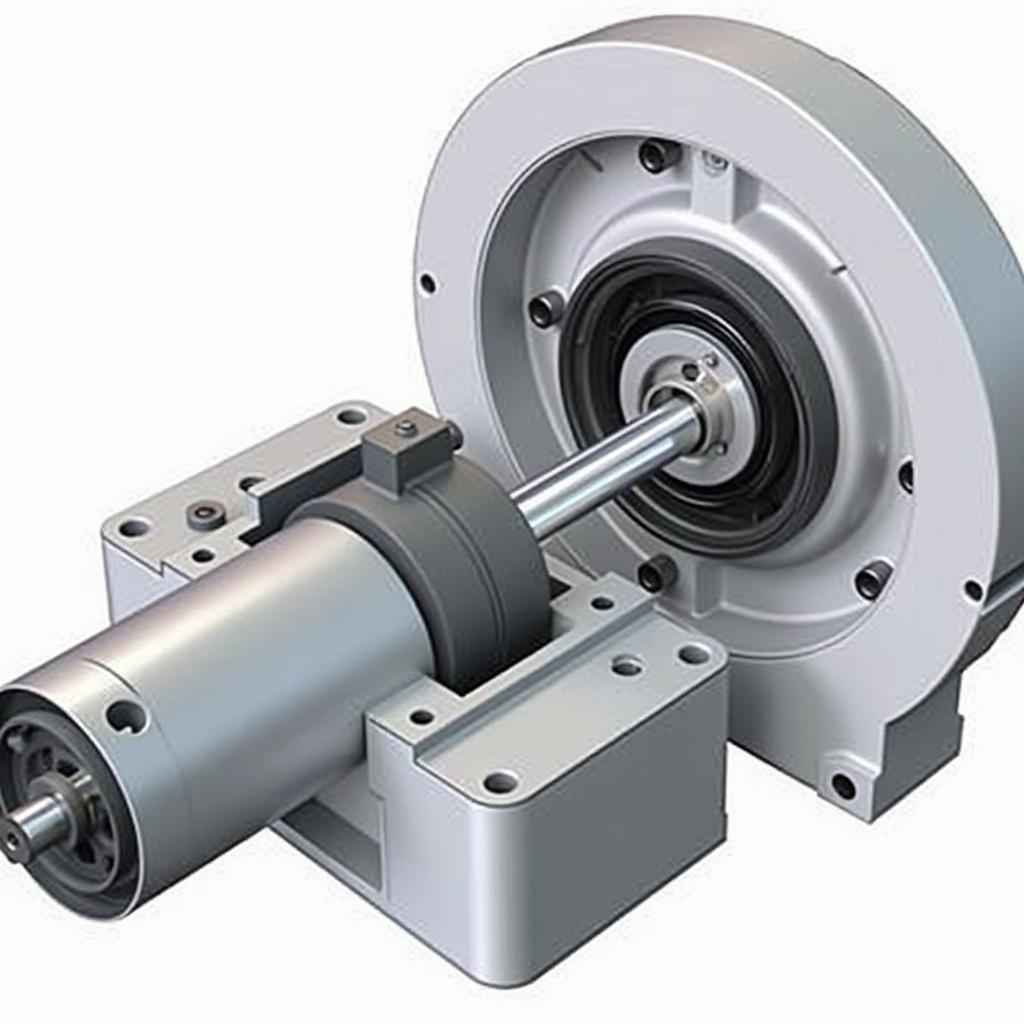

Asean B shaft integrated into industrial machinery

Asean B shaft integrated into industrial machinery

Factors Influencing Asean B Shaft Length Selection

Choosing the appropriate Asean B shaft length involves considering several factors, including:

- Application Requirements: The specific function and operating conditions of the machinery dictate the required shaft length for optimal performance.

- Load and Speed: The amount of load the shaft needs to handle and the rotational speed influence the choice of shaft length to ensure structural integrity.

- Space Constraints: The available space within the equipment design imposes limitations on the maximum allowable shaft length.

Common Asean B Shaft Length Standards

While specific shaft length requirements vary based on application, several common standards exist within the ASEAN region. These standards define specific shaft lengths and tolerances to ensure compatibility and interchangeability.

Troubleshooting Asean B Shaft Length Issues

Identifying and addressing shaft length issues promptly is crucial for maintaining equipment performance and safety. Here are some common problems and solutions:

- Excessive Vibration: This could indicate shaft misalignment due to incorrect shaft length. Reassessing the measurements and adjusting the shaft length accordingly can mitigate vibrations.

- Premature Bearing Failure: Incorrect shaft length can lead to uneven load distribution on bearings, resulting in premature wear. Verifying and correcting shaft length helps ensure optimal bearing life.

- Noise and Heat Generation: Unusual noises or excessive heat from the shaft assembly can signal misalignment or friction caused by improper shaft length.

Conclusion

Understanding Asean B shaft length is paramount for ensuring the seamless operation and longevity of industrial equipment. By adhering to established standards and considering application-specific factors, engineers and technicians can make informed decisions when selecting and maintaining shafts, contributing to enhanced productivity, safety, and overall operational efficiency.

FAQ

1. What are the consequences of using an incorrect Asean B shaft length?

Using the wrong shaft length can lead to misalignment, vibrations, premature wear and tear of components, reduced efficiency, and potential safety hazards.

2. Where can I find information on Asean B shaft length standards?

You can refer to industry publications, standards organizations, and manufacturer catalogs for detailed information on Asean B shaft length standards.

3. How often should I inspect Asean B shafts for wear and tear?

Regular inspections are recommended based on usage and operating conditions. Consult manufacturer guidelines for specific inspection intervals.

4. What are some tips for ensuring accurate Asean B shaft length measurements?

Use precision measuring tools, ensure proper alignment during measurements, and follow established measurement procedures to obtain accurate results.

5. Can I modify an existing Asean B shaft to adjust its length?

Modifying shaft lengths is not recommended as it can compromise the shaft’s structural integrity and affect its performance. It’s best to choose a shaft with the correct length from the outset.

Need Assistance?

For inquiries or assistance regarding Asean B shaft lengths and related technical information, please contact our dedicated support team at:

Phone: 0369020373

Email: [email protected]

Address: Thôn Ngọc Liễn, Hiệp Hòa, Bắc Giang, Việt Nam

Our team is available 24/7 to provide comprehensive support and address your specific needs.