The Asea Fluid Forming Press is a specialized type of metal forming equipment that utilizes high pressure fluids, typically water or oil, to shape metal workpieces. This process, also known as hydroforming, offers significant advantages over traditional stamping methods, especially when manufacturing complex shapes or working with high-strength materials.

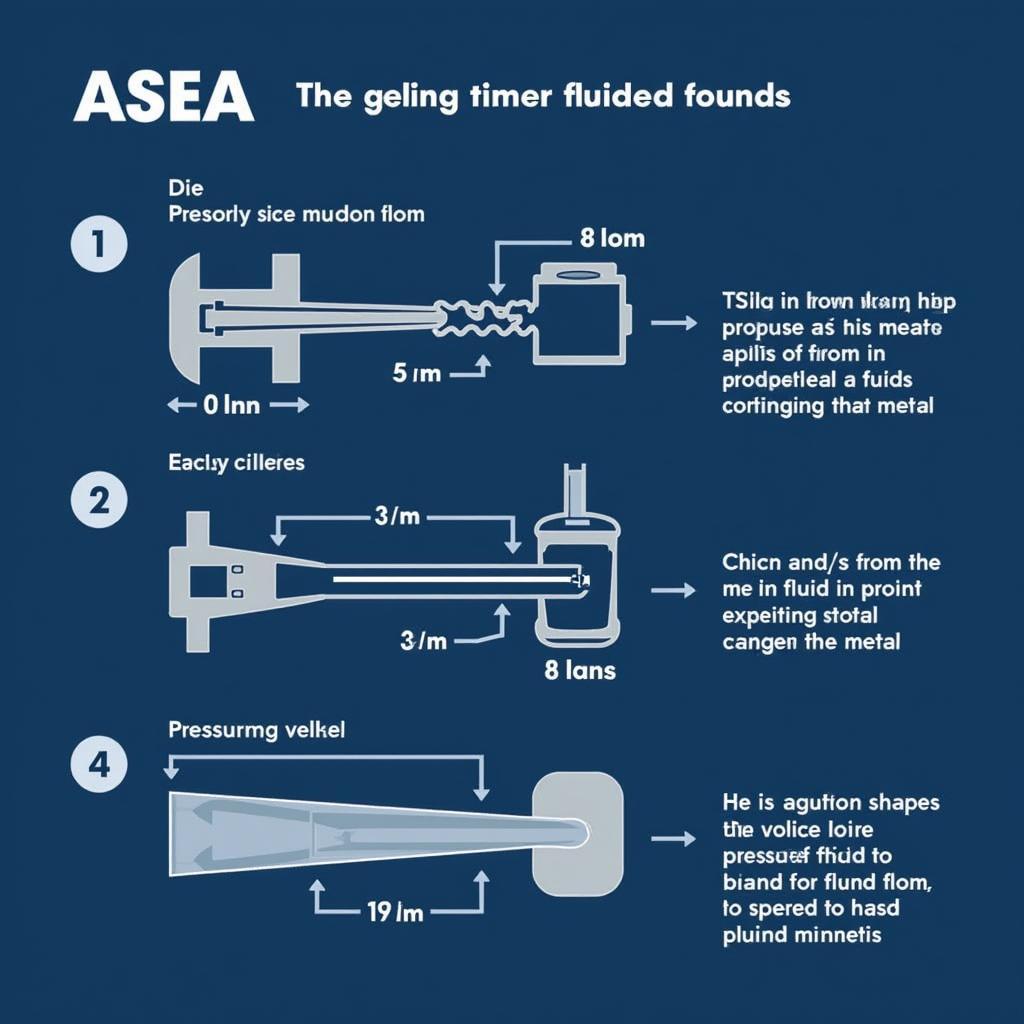

How Does an ASEA Fluid Forming Press Work?

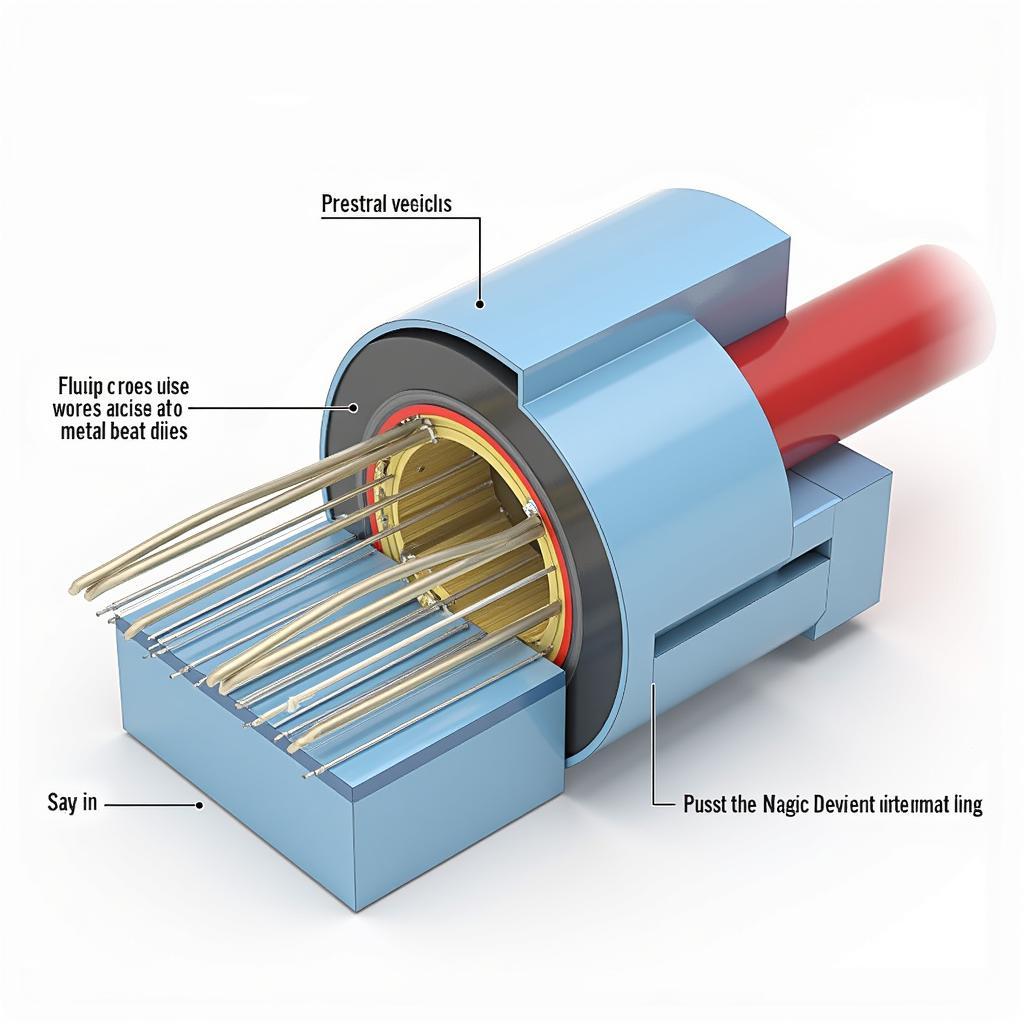

The ASEA fluid forming process starts with a die, which is a pre-shaped mold that mirrors the desired final shape of the workpiece. A metal blank, a flat sheet of metal, is positioned over the die. The die and blank are then loaded into a pressure vessel filled with the forming fluid.

ASEA Fluid Forming Process in Action

ASEA Fluid Forming Process in Action

When the vessel is sealed, high-pressure fluid is pumped into the chamber. This pressure evenly distributes across the blank, forcing it to conform to the contours of the die. The pressure used in ASEA fluid forming presses can reach extremely high levels, often exceeding 10,000 psi, ensuring precise and uniform forming.

Fluid Pressure Distribution on Blank in ASEA Press

Fluid Pressure Distribution on Blank in ASEA Press

After the forming process is complete, the pressure is released, and the shaped workpiece is removed from the die. The result is a component with high dimensional accuracy, excellent surface finish, and improved structural integrity.

Advantages of Using an ASEA Fluid Forming Press

ASEA fluid forming presses offer a number of significant advantages over conventional metal forming methods:

- Complex Shapes: The ability to apply uniform pressure allows for the creation of highly intricate shapes with tight tolerances.

- High-Strength Materials: ASEA fluid forming excels in shaping high-strength materials, such as titanium and high-strength steel alloys, which are difficult to form using traditional methods.

- Improved Strength and Durability: The forming process enhances the material’s grain structure, resulting in increased strength and durability of the finished component.

- Reduced Tooling Costs: While the initial investment in an ASEA press might be higher, the reduced need for multiple dies and tooling changes can lead to lower overall production costs.

Applications of ASEA Fluid Forming

The versatility and advantages of ASEA fluid forming make it suitable for a wide range of industries and applications:

- Automotive: Manufacturing complex parts like fuel tanks, exhaust components, and structural elements.

- Aerospace: Creating lightweight and high-strength components for aircraft structures and engine parts.

- Medical Devices: Producing intricate shapes for implants, surgical instruments, and other medical devices.

- Energy Industry: Forming components for pipelines, pressure vessels, and other critical equipment.

Choosing the Right ASEA Fluid Forming Press

Selecting the appropriate ASEA fluid forming press depends on several factors, including:

- Workpiece Size and Shape: The dimensions and complexity of the desired component will dictate the size and capabilities of the press required.

- Material Type and Thickness: Different materials and thicknesses require varying pressure levels and forming parameters.

- Production Volume: High-volume production might necessitate a press with automated features and faster cycle times.

Various Types of ASEA Fluid Forming Presses

Various Types of ASEA Fluid Forming Presses

Conclusion

The ASEA fluid forming press has revolutionized metal forming, offering a highly precise and efficient method to shape complex components from a variety of materials. As industries continue to demand lighter, stronger, and more intricate parts, the adoption of ASEA fluid forming technology is expected to grow, driving innovation in manufacturing processes across various sectors.

FAQ

1. What types of fluids are commonly used in ASEA fluid forming presses?

Water and oil are the most common fluids used, each offering different properties that might be suitable for specific applications.

2. What is the typical lifespan of an ASEA fluid forming press?

With proper maintenance and depending on usage intensity, these presses can last for several decades.

3. Can ASEA fluid forming be used for prototyping?

Yes, it is well-suited for prototyping due to its ability to create complex shapes with relatively low tooling costs.

4. What are the environmental benefits of using an ASEA fluid forming press?

It’s considered an environmentally friendly process as it generates minimal waste and uses biodegradable fluids.

5. How does the cost of ASEA fluid forming compare to traditional stamping?

While the initial investment might be higher, the long-term cost benefits often outweigh traditional methods, especially for high-complexity parts.

Need assistance with your ASEA fluid forming needs? Contact us at Phone Number: 0369020373, Email: [email protected], or visit us at Thôn Ngọc Liễn, Hiệp Hòa, Bắc Giang, Việt Nam. Our customer support team is available 24/7 to help.