Ase Fat Extraction, or Accelerated Solvent Extraction, is a highly efficient technique used to isolate fats and oils from various matrices. This method utilizes elevated temperatures and pressures to accelerate the extraction process, providing a faster and more effective alternative to traditional methods. In the first 50 words, we introduce the topic of ASE fat extraction, setting the stage for a deeper exploration of this essential analytical technique.

What is ASE Fat Extraction?

ASE fat extraction leverages the power of solvents at high temperatures and pressures to extract lipids. The sample is placed in a sealed extraction cell and subjected to these conditions, allowing for rapid and complete extraction of the target compounds. This process significantly reduces extraction time and solvent consumption compared to traditional Soxhlet extraction, making it an environmentally friendly and cost-effective option. The increased temperature enhances the solubility and diffusivity of the fat, while the elevated pressure keeps the solvent in a liquid state even at high temperatures, ensuring efficient extraction. This method is widely used in food analysis, environmental monitoring, and other fields.

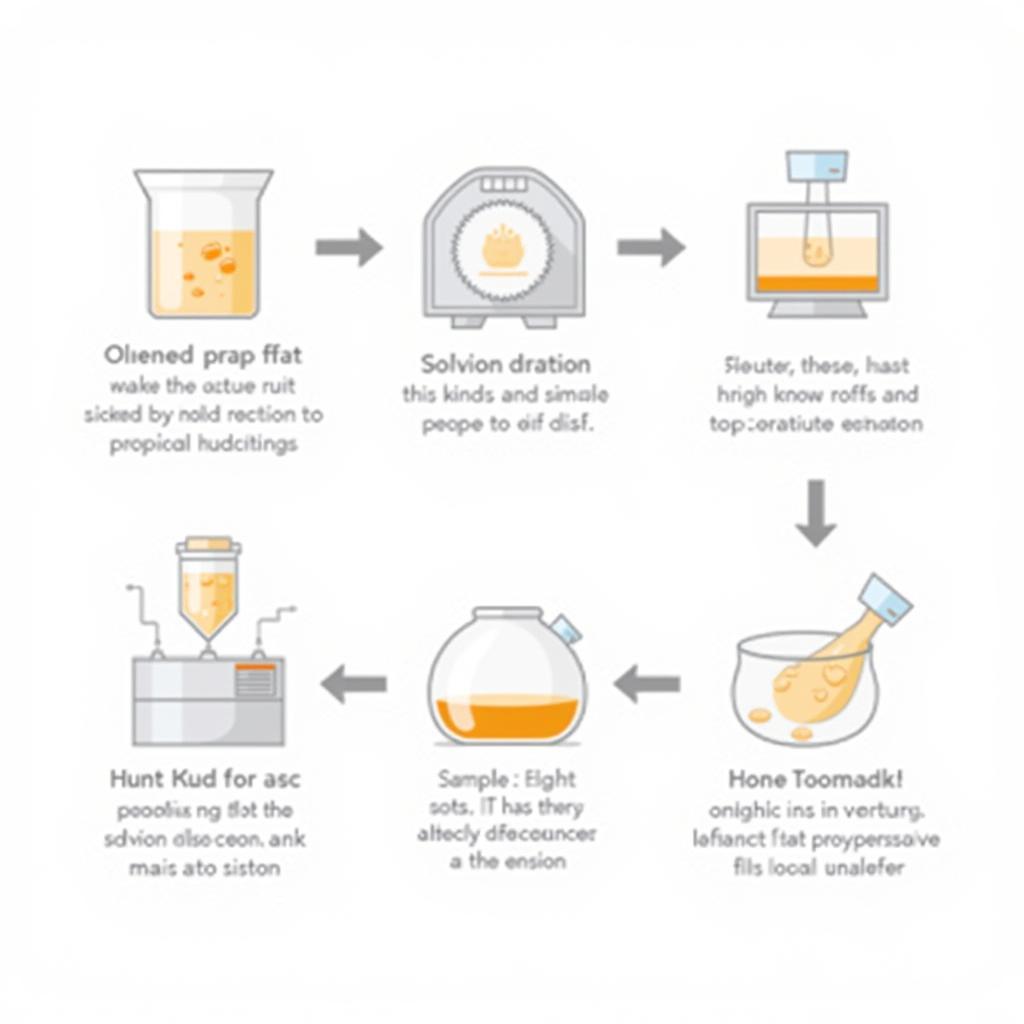

After this introduction, let’s see a quick summary of the process:

- Sample preparation: The sample is dried, ground, and homogenized to ensure uniformity and maximize extraction efficiency.

- Solvent selection: The appropriate solvent is chosen based on the target fat and matrix properties.

- Extraction: The sample is loaded into an extraction cell and placed in the ASE system. The system is programmed with the desired temperature, pressure, and extraction time.

- Collection and analysis: The extracted fat is collected and further analyzed to determine its composition and properties.

ASE fat extraction offers several advantages over traditional methods, including:

- Reduced extraction time: ASE significantly reduces extraction time, often completing the process in minutes rather than hours.

- Reduced solvent consumption: The closed-system design of ASE minimizes solvent use, making it an environmentally friendly choice.

- Improved extraction efficiency: The combination of high temperature and pressure ensures complete extraction of the target compounds.

ASE Fat Extraction Process Illustration

ASE Fat Extraction Process Illustration

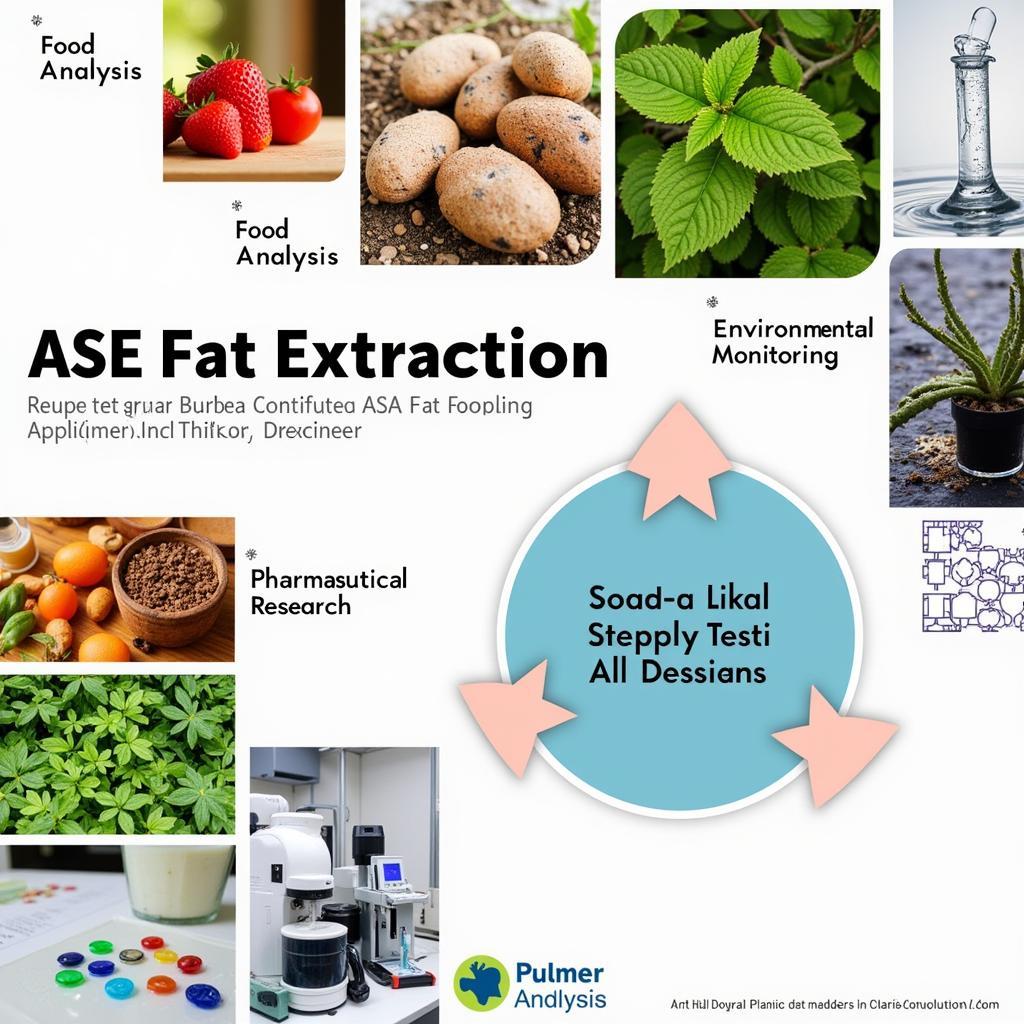

ASE Fat Extraction Applications

ASE offers diverse applications across various sectors, especially for determining fat content in food. It’s a valuable tool for:

- Food Analysis: Determine fat content in various food products like meat, dairy, and processed foods. This information is crucial for nutritional labeling and quality control.

- Environmental Monitoring: Analyze soil and sediment samples for contaminants like pesticides and industrial chemicals.

- Pharmaceutical Research: Extract and analyze active ingredients from plant materials for drug development.

- Polymer Analysis: Extract additives and plasticizers from polymers for quality control and material characterization.

The accelerated solvent extraction ASE 350 is a widely used system in these applications.

Diverse Applications of ASE Fat Extraction

Diverse Applications of ASE Fat Extraction

Optimizing ASE Fat Extraction

Several factors influence the efficiency of ASE fat extraction. Consider these tips for optimal results:

- Sample preparation: Proper grinding and homogenization ensure consistent extraction.

- Solvent selection: Choose the right solvent for your target fat and matrix.

- Temperature and pressure: Optimize these parameters for efficient extraction without degrading the target compounds. An ASE extraction cell is crucial in this process.

“Proper sample preparation is the cornerstone of successful ASE fat extraction,” says Dr. Amelia Tan, a food scientist at the National University of Singapore. “Consistent particle size and homogeneity are essential for reproducible results.”

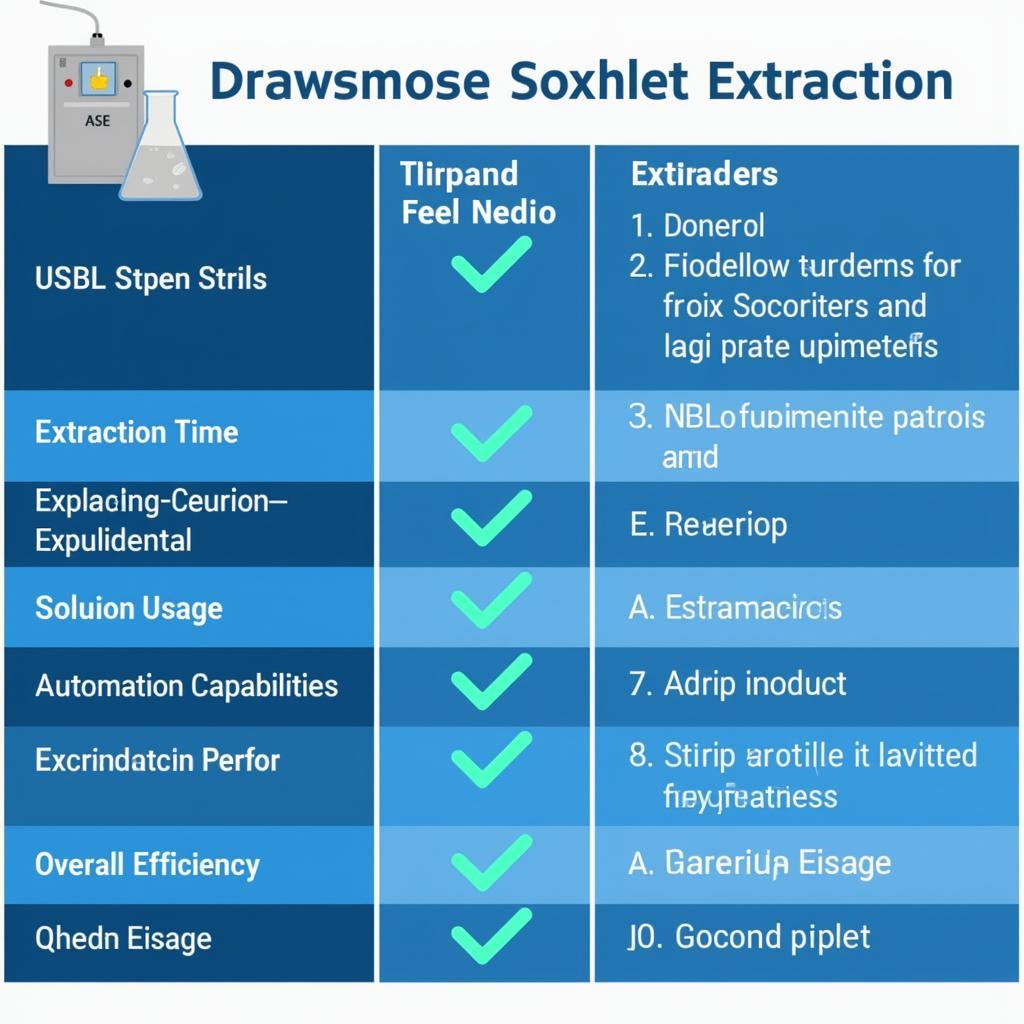

ASE vs. Traditional Soxhlet Extraction

ASE offers numerous advantages over traditional Soxhlet extraction:

- Speed: ASE is significantly faster, often completing extractions in minutes compared to hours for Soxhlet.

- Solvent Usage: ASE uses considerably less solvent, reducing environmental impact and costs.

- Automation: ASE is more readily automated, streamlining the workflow and minimizing manual labor.

“The shift from Soxhlet to ASE has been a game-changer in our lab,” shares Dr. Maria Santos, an environmental chemist at the University of the Philippines. “The time and solvent savings are remarkable, allowing us to process more samples efficiently.” accelerated solvent extraction ase 350 helps us achieve that. You might also want to check out information about ASE extraction cell.

Comparison of ASE and Soxhlet Extraction Methods

Comparison of ASE and Soxhlet Extraction Methods

Conclusion

ASE fat extraction offers a rapid, efficient, and environmentally friendly alternative to traditional methods. Its versatility and numerous advantages make it a powerful tool for diverse applications, from food analysis to environmental monitoring. By optimizing parameters like sample preparation, solvent selection, and extraction conditions, ASE fat extraction ensures accurate and reliable results, driving advancements across various fields. Understanding ASE is crucial for anyone involved in fat analysis. acp ases enzymes might also be of interest if you are working in related fields. Also, for broader context, understanding the ASEAN 6 member countries can be helpful.

FAQ

- What are the main advantages of ASE fat extraction? Speed, reduced solvent use, and improved efficiency.

- What types of samples can be analyzed using ASE? Food, environmental, pharmaceutical, and polymer samples.

- How does ASE compare to Soxhlet extraction? ASE is faster, uses less solvent, and is more easily automated.

- What factors affect the efficiency of ASE? Sample preparation, solvent selection, temperature, and pressure.

- What are some common applications of ASE in the food industry? Determining fat content in various food products for nutritional labeling and quality control.

- How does temperature influence ASE? Higher temperatures increase the solubility and diffusivity of the fat.

- What is the role of pressure in ASE? High pressure keeps the solvent in a liquid state, even at elevated temperatures.

Need assistance? Contact us 24/7: Phone: 0369020373, Email: [email protected], Address: Thon Ngoc Lien, Hiep Hoa, Bac Giang, Vietnam.