Are you looking for the ASE recommended dimensions for a tee? Understanding these dimensions is crucial for ensuring proper fit and functionality in various applications. Whether you’re a professional engineer or a DIY enthusiast, knowing the correct specifications can save you time, money, and potential headaches down the line. This article will delve into the details of ASE tee dimensions, providing valuable insights and practical advice to help you make informed decisions.

Decoding ASE Tee Dimensions: A Comprehensive Guide

ASE, likely referring to a specific standard or organization, dictates particular dimensions for tees to ensure consistency and compatibility across different projects. While the exact standard being referenced may vary depending on the context (e.g., plumbing, electrical, structural), this article will provide a general overview of the key dimensions typically associated with tees and how to interpret them. Knowing the “Ase Recommended Dimensions For Tee” is essential for ensuring a secure and efficient connection.

Key Dimensions to Consider

When working with tees, several critical dimensions need to be considered:

- Run Dimension: This refers to the diameter of the main pipe or conduit to which the tee connects.

- Branch Dimension: This is the diameter of the smaller pipe or conduit that branches off from the tee.

- Center-to-End Dimension: This measurement represents the distance from the center of the run to the end of the branch.

- Overall Length: This dimension indicates the total length of the tee fitting.

These dimensions are usually expressed in inches or millimeters and are crucial in selecting the appropriate tee for your specific application. For example, using a tee with an incorrect run dimension can lead to leaks or weak connections.

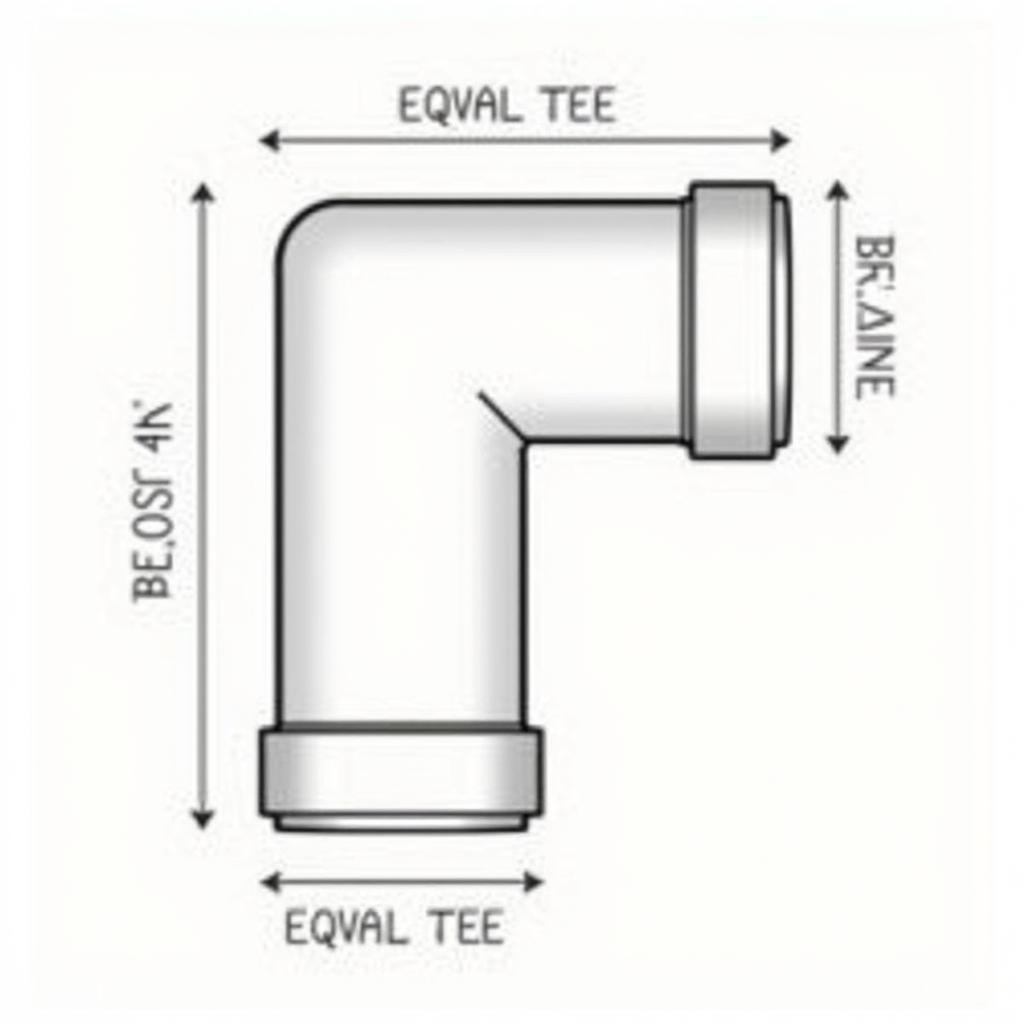

ASE Tee Dimensions Diagram

ASE Tee Dimensions Diagram

Understanding the difference between an equal tee (where the run and branch dimensions are the same) and a reducing tee (where the branch dimension is smaller than the run dimension) is crucial when referencing “ase recommended dimensions for tee”.

Why ASE Recommendations Matter

Adhering to ASE recommendations provides several benefits:

- Compatibility: Ensures the tee fits correctly with other components in the system.

- Performance: Optimizes flow and minimizes pressure drop.

- Safety: Reduces the risk of leaks, bursts, and other failures.

- Code Compliance: Meets industry standards and regulations.

By following the “ase recommended dimensions for tee”, you’re ensuring the integrity and reliability of your system.

Finding the Right ASE Tee

To find the right ASE tee, consult the relevant standards documents or manufacturer catalogs. These resources will provide detailed specifications and dimensional drawings for various tee types and sizes. Always double-check the dimensions before making a purchase to avoid costly mistakes.

How to Interpret ASE Tee Specifications

ASE specifications often include a combination of letters and numbers that represent the tee’s dimensions and material properties. Learning to decipher these codes is essential for selecting the correct fitting. For instance, the code might indicate the material type (e.g., stainless steel, PVC), the pressure rating, and the specific dimensions. Understanding these codes is critical when searching for “ase recommended dimensions for tee.”

Common ASE Tee Materials

ASE standards may cover various materials for tee fittings, including:

- Steel: Known for its strength and durability.

- Stainless Steel: Offers excellent corrosion resistance.

- PVC: A cost-effective option for non-pressure applications.

- Copper: Commonly used in plumbing systems.

The material choice will depend on the specific application and environmental conditions.

ASE Tee Material Comparison Chart

ASE Tee Material Comparison Chart

Conclusion

Understanding and applying the “ase recommended dimensions for tee” is crucial for successful project completion. By carefully considering the key dimensions, material properties, and relevant standards, you can ensure a proper fit, optimal performance, and long-lasting reliability. Using the correct dimensions avoids potential issues and contributes to a safe and efficient system.

FAQ

- What does ASE stand for in the context of tee dimensions? (This will depend on the specific application, but it likely refers to a specific standard or organization.)

- Where can I find the ASE recommended dimensions for a specific tee? (Consult relevant standards documents or manufacturer catalogs.)

- What are the consequences of using an incorrect tee size? (Leaks, weak connections, system failure.)

- What are the different types of tees available? (Equal tees, reducing tees, etc.)

- What materials are commonly used for ASE tees? (Steel, stainless steel, PVC, copper, etc.)

- How do I interpret ASE tee specification codes? (Refer to the relevant standards document or manufacturer’s guide.)

- Are there different ASE standards for different applications? (Yes, standards may vary depending on the industry and application.)

You may also find the following article helpful: ase 8x16x16 steel pull box

Need Help?

When you need assistance with “ase recommended dimensions for tee” or any other inquiries, don’t hesitate to contact us. Call: 0369020373, Email: [email protected], or visit us at: Thôn Ngọc Liễn, Hiệp Hòa, Bắc Giang, Việt Nam. We have a 24/7 customer support team ready to assist you.