Ase Fcbga Packaging is a critical component in today’s advanced electronics, offering a high-density interconnect solution for complex integrated circuits. This packaging technology plays a vital role in enabling the performance and miniaturization of devices across various sectors, from consumer electronics to high-performance computing.

What is ASE FCBGA Packaging?

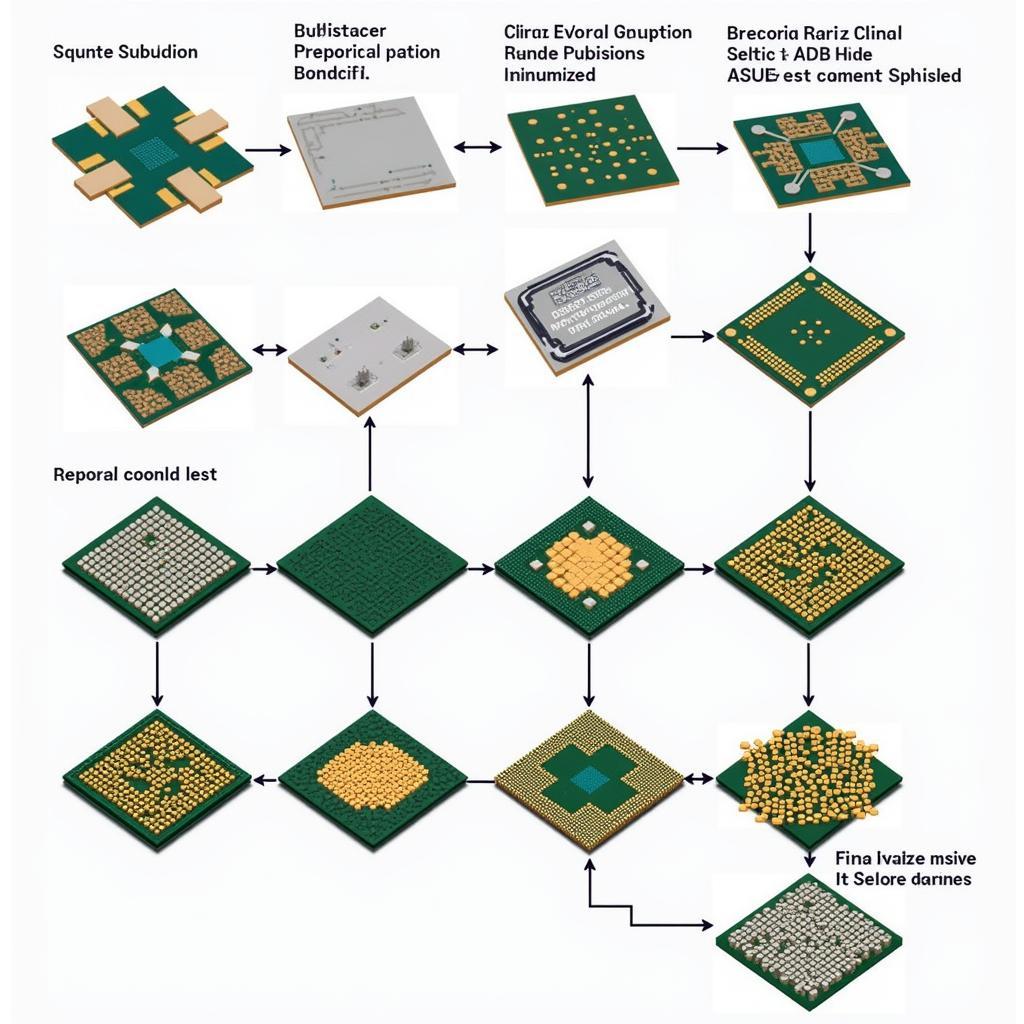

Flip-chip ball grid array (FCBGA) packaging, particularly by ASE, a leading semiconductor assembly and test services provider, is a surface-mount packaging technology that connects the integrated circuit (IC) to the printed circuit board (PCB). Unlike traditional packaging methods, the IC is flipped upside down and connected directly to the substrate using solder bumps, creating a shorter electrical path and improved performance. ASE’s expertise in this field ensures reliable and high-quality FCBGA solutions for demanding applications. These solder bumps, arranged in a grid array, form the connection points to the PCB, enabling efficient heat dissipation and high I/O counts. This makes ase fcbga packaging ideal for high-performance processors, graphics processing units (GPUs), and other complex chips.

ASE FCBGA packaging addresses the growing need for smaller, more powerful devices. As technology continues to advance, components are becoming increasingly integrated, demanding more sophisticated packaging solutions. FCBGA packaging meets this challenge by offering a robust and efficient way to connect complex ICs, contributing significantly to the evolution of electronics.

Advantages of ASE FCBGA Packaging

- Superior Performance: The direct connection between the IC and substrate reduces signal path length and improves electrical performance, leading to faster processing speeds and lower power consumption.

- Enhanced Thermal Management: The grid array of solder bumps allows for efficient heat dissipation, essential for high-performance chips that generate significant heat.

- High Density Interconnect: FCBGA packaging enables a large number of connections between the IC and the PCB, supporting the complex requirements of advanced electronics.

- Smaller Footprint: Flipping the chip and connecting it directly to the substrate allows for a smaller overall package size, crucial for miniaturization of electronic devices.

“ASE’s commitment to innovation in FCBGA packaging is evident in their consistent development of advanced solutions. Their focus on performance, reliability, and miniaturization makes them a key player in the semiconductor industry,” states Dr. Anya Sharma, a leading semiconductor packaging expert.

ASE FCBGA packaging in modern electronic devices

ASE FCBGA packaging in modern electronic devices

Applications of ASE FCBGA Packaging

ASE FCBGA packaging finds applications in a wide range of industries:

- Consumer Electronics: Smartphones, tablets, and laptops utilize ase semiconductor packaging for powerful processors and graphics chips.

- High-Performance Computing: Servers and data centers rely on FCBGA packaging for high-performance processors and networking equipment.

- Automotive Electronics: Advanced driver-assistance systems (ADAS) and other automotive electronics utilize FCBGA packaging for complex sensors and control units.

- Telecommunications: Networking infrastructure and communication devices utilize FCBGA packaging for high-speed data processing and transmission.

“The reliability and performance of ASE FCBGA packaging are critical factors in our choice of components. Their solutions allow us to push the boundaries of performance in our high-performance computing systems,” says Mr. Ben Nguyen, a Senior Systems Engineer at a leading technology company.

ASE FCBGA packaging manufacturing process

ASE FCBGA packaging manufacturing process

Conclusion

ASE FCBGA packaging is a vital technology in the semiconductor industry, enabling the development of smaller, more powerful, and more efficient electronic devices. Its advantages in performance, thermal management, and interconnect density make it a key enabler for innovation across various sectors. As technology continues to evolve, ASE fcbga packaging will undoubtedly play an increasingly important role in shaping the future of electronics.

FAQs

-

What does FCBGA stand for?

FCBGA stands for Flip-Chip Ball Grid Array. -

What are the key benefits of ASE FCBGA packaging?

Key benefits include enhanced performance, better thermal management, and high-density interconnect capabilities. -

What industries use ASE FCBGA packaging?

Industries include consumer electronics, high-performance computing, automotive, and telecommunications. -

How does FCBGA packaging differ from traditional packaging methods?

The IC is flipped and directly connected to the substrate using solder bumps, creating a shorter electrical path and improved performance. -

Why is ASE a leading provider of FCBGA packaging?

ASE’s expertise and commitment to innovation ensure reliable and high-quality FCBGA solutions.

For further assistance, please contact us at Phone Number: 0369020373, Email: [email protected] or visit our address: Thon Ngoc Lien, Hiep Hoa, Bac Giang, Vietnam. We have a 24/7 customer service team.