Drum brakes, a critical component of many vehicles, are a frequent topic of discussion among automotive technicians, especially when preparing for the ASE certification exams. This comprehensive guide addresses common Ase Drum Brake Questions, providing valuable insights into their functionality, maintenance, and troubleshooting.

Understanding drum brakes is essential for any aspiring automotive professional. From the basic components to advanced diagnostic techniques, mastering this system is key to passing the ASE exams and excelling in your career. This article will delve into the intricacies of drum brakes, answering common questions and clarifying misconceptions. Let’s explore the world of drum brakes and equip you with the knowledge you need. You can further supplement your knowledge by referring to our ASE B5 Study Guide.

Understanding the Basics of Drum Brakes

What are the core components of a drum brake system? Drum brakes consist of a rotating drum, brake shoes, wheel cylinder, and various springs and hardware. The shoes press against the drum’s inner surface to create friction and slow the vehicle. This seemingly simple system requires precise adjustments and regular maintenance for optimal performance.

Common Drum Brake Components and Their Functions

Each part plays a vital role in the overall function of the drum brake system:

- Drum: The rotating component against which the brake shoes press.

- Brake Shoes: Friction material that creates the stopping force.

- Wheel Cylinder: Hydraulic component that pushes the shoes outward.

- Springs: Retract the shoes when the brakes are released.

- Hardware: Various clips, pins, and adjusters that ensure proper assembly and operation.

Understanding the function of each component is crucial for diagnosing and repairing drum brake issues. For a more comprehensive overview of brake systems, check out our ASE Brakes Study Guide PDF.

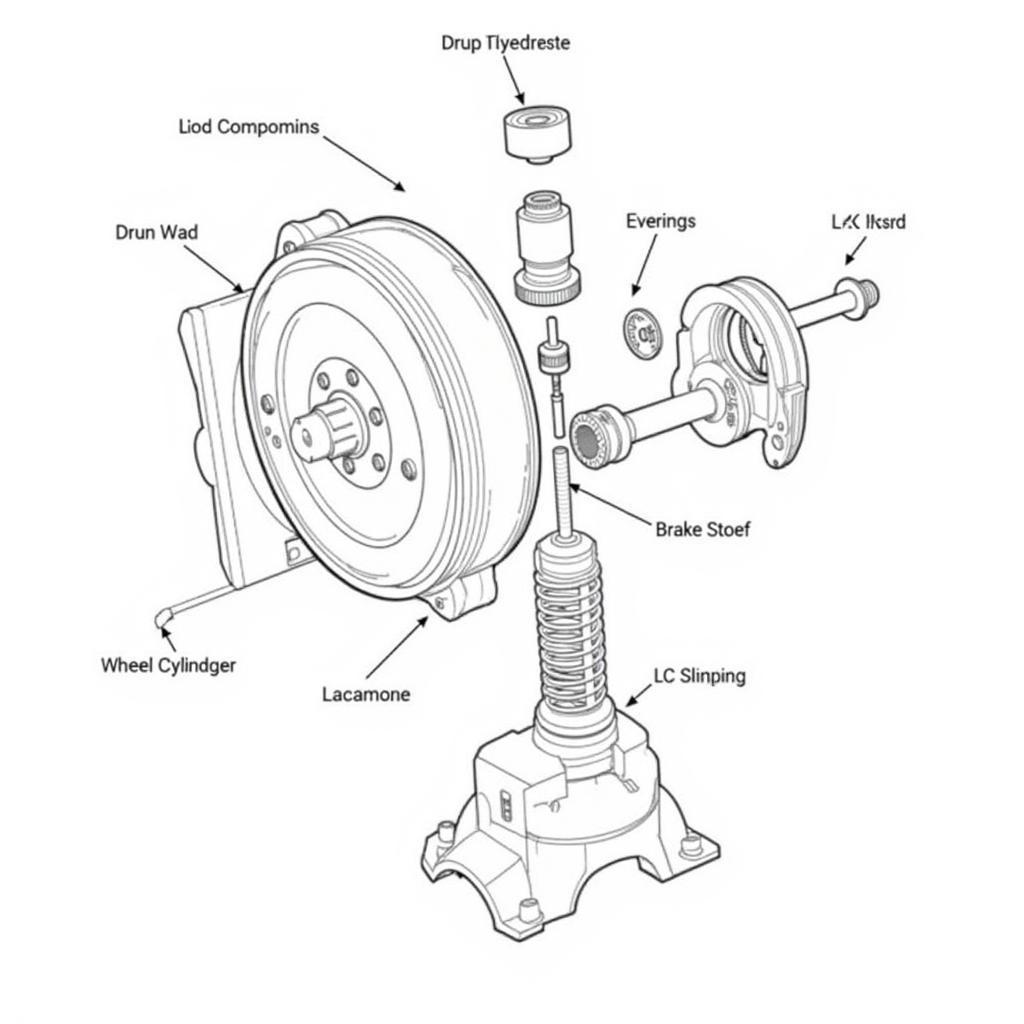

Diagram of Drum Brake Components

Diagram of Drum Brake Components

Troubleshooting Common Drum Brake Problems

Diagnosing drum brake issues can be challenging. Understanding the symptoms and their potential causes is crucial.

Identifying and Addressing Brake Noise

Squealing, grinding, or other noises emanating from the drum brakes can indicate various problems:

- Squealing: Often caused by worn brake shoes or improperly lubricated hardware.

- Grinding: A sign of metal-on-metal contact, likely due to severely worn shoes or a damaged drum.

- Groaning or thumping: May indicate a problem with the drum or backing plate.

Proper inspection and diagnosis are essential for addressing these issues effectively.

Dealing with Uneven Brake Application

Uneven brake application can pull the vehicle to one side during braking:

- Causes: This can be caused by a seized wheel cylinder, unevenly adjusted brakes, or contaminated brake linings.

- Solutions: Addressing this issue typically involves repairing or replacing the faulty component and ensuring proper adjustment.

Practice tests can help you prepare for diagnosing these types of problems. Explore our Brake ASE Practice Test for valuable practice scenarios.

Maintenance and Adjustment of Drum Brakes

Regular maintenance is crucial for ensuring the longevity and optimal performance of drum brakes.

How to Properly Adjust Drum Brakes

Proper adjustment ensures even braking and prevents premature wear. This procedure typically involves adjusting the star wheel adjuster until the shoes lightly contact the drum. Accurate adjustment is essential for optimal braking performance. You might find our ASE Practice Tests L1 helpful in preparing for this aspect of the ASE exam.

Importance of Regular Inspection and Cleaning

Regular inspection and cleaning of drum brake components can prevent many problems. This includes checking for wear, leaks, and damage, as well as cleaning and lubricating the moving parts.

Conclusion

Mastering the intricacies of drum brakes is crucial for automotive technicians. Understanding the components, troubleshooting techniques, and maintenance procedures is essential for success in the field and on the ASE certification exams. This guide has provided answers to frequently asked ase drum brake questions, equipping you with the knowledge to diagnose and repair these systems effectively. By continuously learning and practicing, you can become proficient in working with drum brakes. Now that you have a deeper understanding of ase drum brake questions, you’re well-equipped to tackle any challenge related to this essential braking system.

FAQ

- What are the common signs of worn drum brakes?

- How often should drum brakes be inspected?

- What tools are needed for adjusting drum brakes?

- How can I tell if a wheel cylinder is seized?

- What are the potential consequences of neglecting drum brake maintenance?

- What are the different types of drum brake hardware?

- How can I differentiate between drum brake noise and other brake system noises?

Common Scenarios with ASE Drum Brake Questions

- Scenario 1: A customer complains of a grinding noise coming from the rear wheels. What are the potential causes?

- Scenario 2: The vehicle pulls to one side when braking. How would you diagnose this issue?

- Scenario 3: During an inspection, you notice excessive wear on one brake shoe. What could be the reason?

Further Reading and Resources

For additional information on ASE certifications and related topics, you can explore other relevant articles on our website. You might find our ASE Inspection Sheet useful for further learning.

Contact Us

Need help? Contact us 24/7: Phone: 0369020373, Email: [email protected], Address: Thon Ngoc Lien, Hiep Hoa, Bac Giang, Vietnam.