Ase Wafer Test is a crucial step in the semiconductor manufacturing process, ensuring the quality and reliability of integrated circuits before they are packaged and assembled into electronic devices. This process involves a series of rigorous tests performed on silicon wafers, identifying any defects or malfunctions early on. It plays a vital role in maintaining high performance and minimizing costly recalls down the line. Let’s delve deeper into the intricacies of ASE wafer test and explore its importance in the semiconductor industry.

Understanding the Importance of ASE Wafer Test

Wafer testing allows manufacturers, like ASE Singapore Pte Ltd Intel, to identify faulty chips early in the production process. This early detection not only saves resources but also ensures the final product meets the required quality standards. The process is a complex undertaking, demanding precision, advanced technology, and skilled expertise.

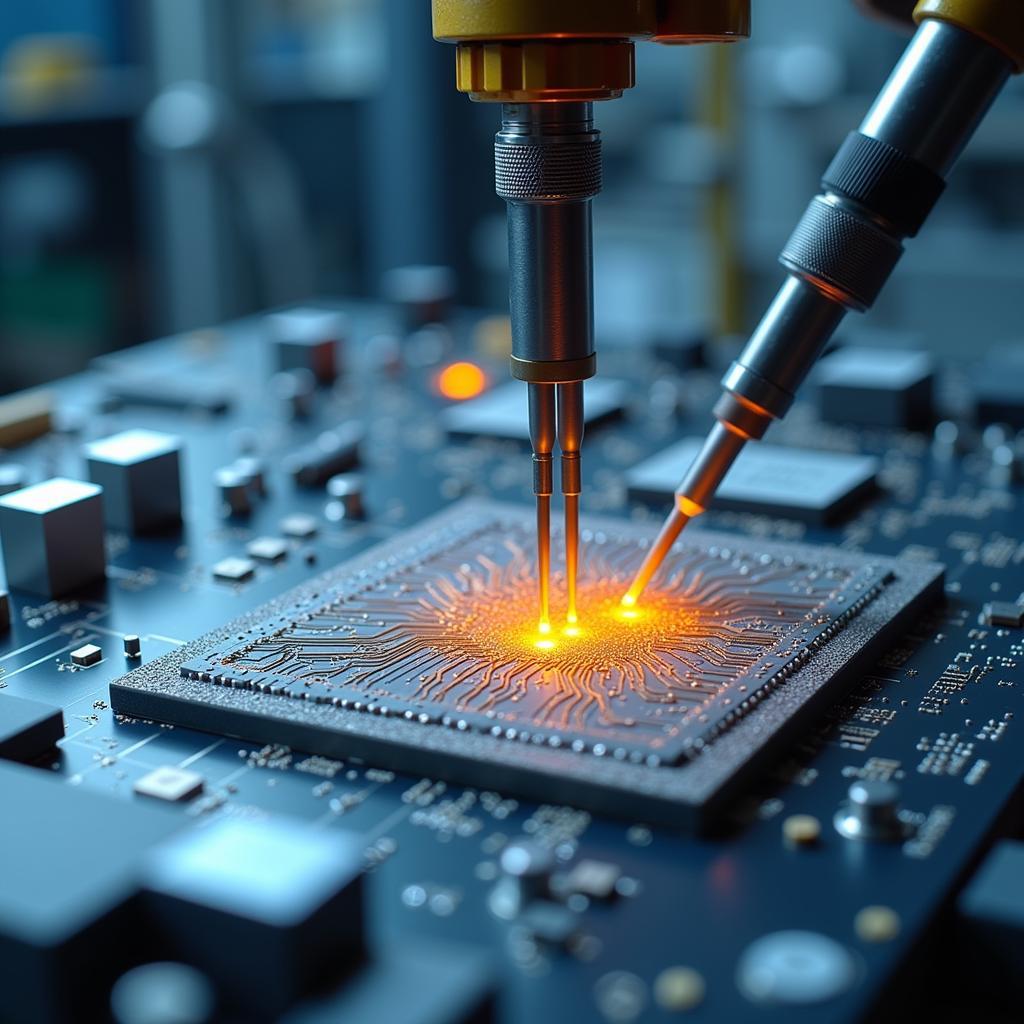

Wafer testing typically involves probing individual die on the wafer using specialized equipment. These probes make electrical contact with the die, allowing for various tests to be conducted, including functionality, performance, and parametric measurements. The data gathered from these tests helps pinpoint defective die, which are then marked for exclusion during the subsequent packaging stage. This meticulous approach ensures only functional and high-performing chips make their way into consumer products.

Types of ASE Wafer Tests

Several types of wafer tests are employed to evaluate different aspects of the chip’s performance. These tests can range from simple continuity checks to complex performance evaluations under varying operating conditions. Some of the common types include:

- Functional testing: Verifies the basic functionality of the chip, ensuring it performs its intended operations.

- Parametric testing: Measures specific electrical parameters, such as voltage and current levels, to ascertain the chip’s performance within the specified limits.

- Burn-in testing: Subjects the chip to extreme operating conditions, such as high temperatures and voltages, to identify any latent defects.

ASE Wafer Test Process in Detail

ASE Wafer Test Process in Detail

The Role of ASE in Wafer Test

ASE, a leading provider of semiconductor manufacturing services, plays a significant role in the wafer testing arena. With its cutting-edge technology and vast experience, ASE offers a wide range of wafer testing solutions to cater to various customer needs. The company leverages state-of-the-art equipment and automated processes to ensure high throughput and accuracy in its testing procedures. This commitment to quality makes ASE a trusted partner for semiconductor companies worldwide. Learn more about this company through this link: ASE Inc Kaohsiung Taiwan.

Benefits of Partnering with ASE for Wafer Test

Choosing ASE for wafer testing provides several key benefits, including:

- Reduced time-to-market: ASE’s efficient testing processes enable faster turnaround times, allowing companies to launch their products sooner.

- Improved product quality: Rigorous testing ensures high product quality and reliability, reducing the risk of costly recalls and customer dissatisfaction.

- Cost optimization: By identifying defects early on, ASE’s wafer testing solutions help minimize material waste and reduce overall production costs.

Key Advantages of Using ASE for Wafer Testing

Key Advantages of Using ASE for Wafer Testing

The Future of ASE Wafer Test

What does the future hold for ASE wafer test? As technology evolves, wafer testing techniques are continuously advancing to keep pace with the increasing complexity of integrated circuits. The growing demand for higher performance and miniaturization calls for more sophisticated testing methodologies. ASE is at the forefront of these advancements, investing heavily in research and development to innovate new testing solutions. The company’s forward-thinking approach ensures it remains a leader in the wafer testing domain, providing customers with the most advanced and reliable testing services. For further information regarding the company, visit ASE PLC M22 0RR.

“The future of wafer test lies in automation and data analytics,” says Dr. Alan Tan, a leading expert in semiconductor testing. “ASE is well-positioned to lead this transformation with its expertise in both areas.”

“With the increasing complexity of chips, ensuring reliability is more critical than ever,” adds Ms. Maria Sanchez, a veteran engineer in the semiconductor industry. “ASE’s commitment to quality and innovation makes them a valuable partner in navigating this challenge.” You can also check out more about ASE PLC.

Conclusion

ASE wafer test is an indispensable part of the semiconductor manufacturing process, ensuring the quality and reliability of integrated circuits. With its advanced technology, expertise, and commitment to innovation, ASE stands out as a leading provider of wafer testing solutions. By partnering with ASE, semiconductor companies can benefit from reduced time-to-market, improved product quality, and optimized costs. As technology continues to evolve, ASE is poised to shape the future of wafer test, driving innovation and ensuring the continued advancement of the semiconductor industry. For further information regarding the company’s advancements, visit the Advanced Semiconductor Engineering ASE Group.

FAQ

- What is ASE wafer test?

- Why is wafer testing important?

- What are the different types of wafer tests?

- What are the benefits of partnering with ASE for wafer test?

- What is the future of ASE wafer test?

- How does ASE ensure the accuracy of its testing procedures?

- What types of chips does ASE specialize in testing?

Need further assistance? Contact us 24/7.

Phone: 0369020373

Email: [email protected]

Address: Thôn Ngọc Liễn, Hiệp Hòa, Bắc Giang, Việt Nam.