The term “Ase Cut Surface” often appears in scientific literature, particularly in materials science and surface chemistry. It refers to a surface created by cutting a material along a specific crystallographic plane using Atomic Simulation Environment (ASE), a powerful Python package for atomic-scale simulations. Let’s explore the nuances of creating and analyzing these surfaces and their significance in various scientific domains. After the initial cut, the surface may undergo relaxation or reconstruction, affecting its properties.

Understanding how to manipulate and analyze these surfaces within ASE is crucial for researchers exploring material properties. You can find helpful tools like ASE calculators gpaw at ase calculators gpaw.

Defining the ASE Cut Surface

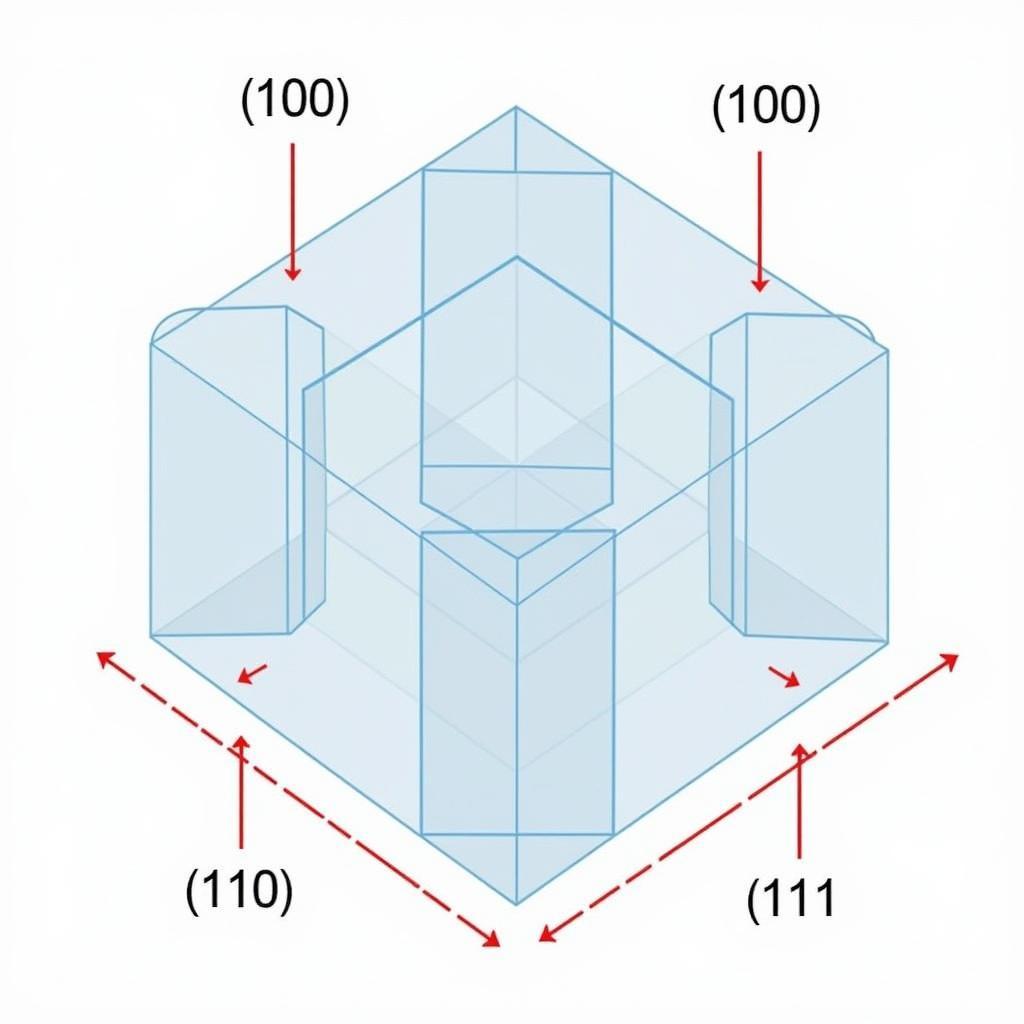

An ASE cut surface is essentially a two-dimensional slice through a three-dimensional material. The plane along which the material is cut is defined by Miller indices, a notation system used in crystallography to describe the orientation of crystal planes. By specifying the desired Miller indices within the ASE framework, researchers can create a variety of surface structures. This precision allows for targeted investigations of how surface structure influences material properties. Different cut surfaces can exhibit significantly different chemical reactivities, electronic properties, and catalytic activities.

Specifying Miller Indices for the Cut

The process of creating an ase cut surface begins with selecting the appropriate Miller indices. These indices, represented by three integers (hkl), determine the orientation of the cutting plane relative to the crystal lattice. For instance, a (100) surface represents a cut parallel to the x-y plane of the crystal, while a (111) surface represents a cut along a different, more complex plane. The choice of Miller indices has profound implications for the resulting surface structure and properties.

ASE Cut Surface and Miller Indices

ASE Cut Surface and Miller Indices

Applications of ASE Cut Surfaces

The study of ase cut surfaces has wide-ranging applications across various scientific disciplines. From understanding catalytic reactions to designing new electronic devices, the ability to model and analyze these surfaces is invaluable. For example, in catalysis, the arrangement of atoms on the surface plays a crucial role in determining the efficiency of a catalytic process.

If you are interested in exploring graphene surfaces within ASE, you might find valuable information at ase graphene surface.

Surface Energy Calculations

One key application of ASE cut surfaces is the calculation of surface energy. This property reflects the thermodynamic stability of a particular surface and influences phenomena such as crystal growth and surface reconstruction. By using ASE to model different cut surfaces, researchers can determine the most stable configurations. This information can be critical for designing materials with desired properties, such as resistance to corrosion or improved adhesion.

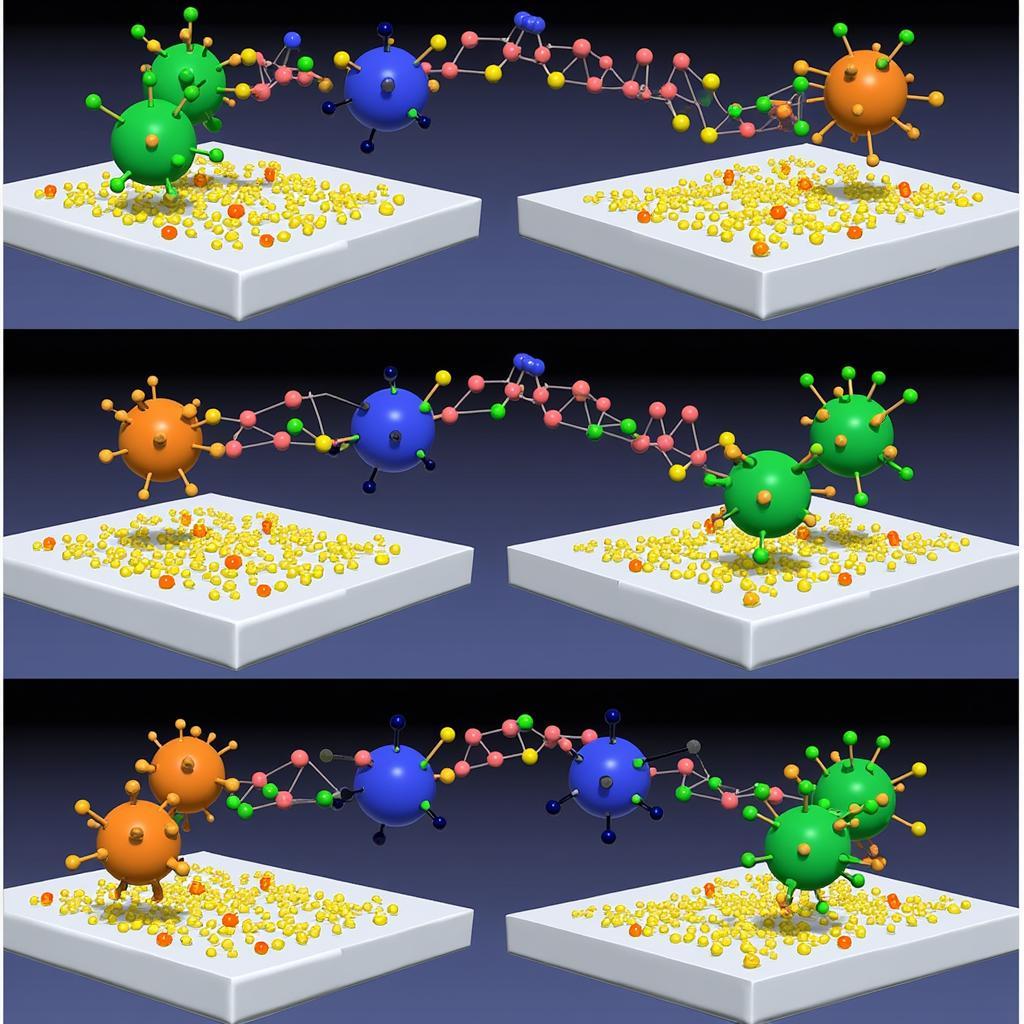

Simulating Surface Reactions

ASE also enables the simulation of chemical reactions on cut surfaces. By introducing reactant molecules to the surface model, researchers can study how the surface structure influences the reaction pathway and kinetics. This capability provides valuable insights into catalytic processes and can guide the development of new and improved catalysts.

Simulating Surface Reactions on ASE Cut Surfaces

Simulating Surface Reactions on ASE Cut Surfaces

Analyzing Electronic Structure

The electronic structure of a material is significantly altered at its surface. ASE allows researchers to calculate the electronic properties of cut surfaces, such as the density of states and band structure. These calculations can reveal important information about surface reactivity and conductivity, which is crucial for applications in areas like electronics and sensor technology.

Challenges and Future Directions

While ASE provides powerful tools for working with cut surfaces, some challenges remain. Accurately representing the complex interactions at the surface can be computationally demanding, and developing more efficient algorithms is an ongoing area of research. Furthermore, incorporating the effects of environmental factors, such as temperature and pressure, into surface simulations remains a complex task.

Even seemingly unrelated searches like “como se ase el guacamole” might lead users to explore related concepts and terminology. You can explore more at como se ase el guacamole.

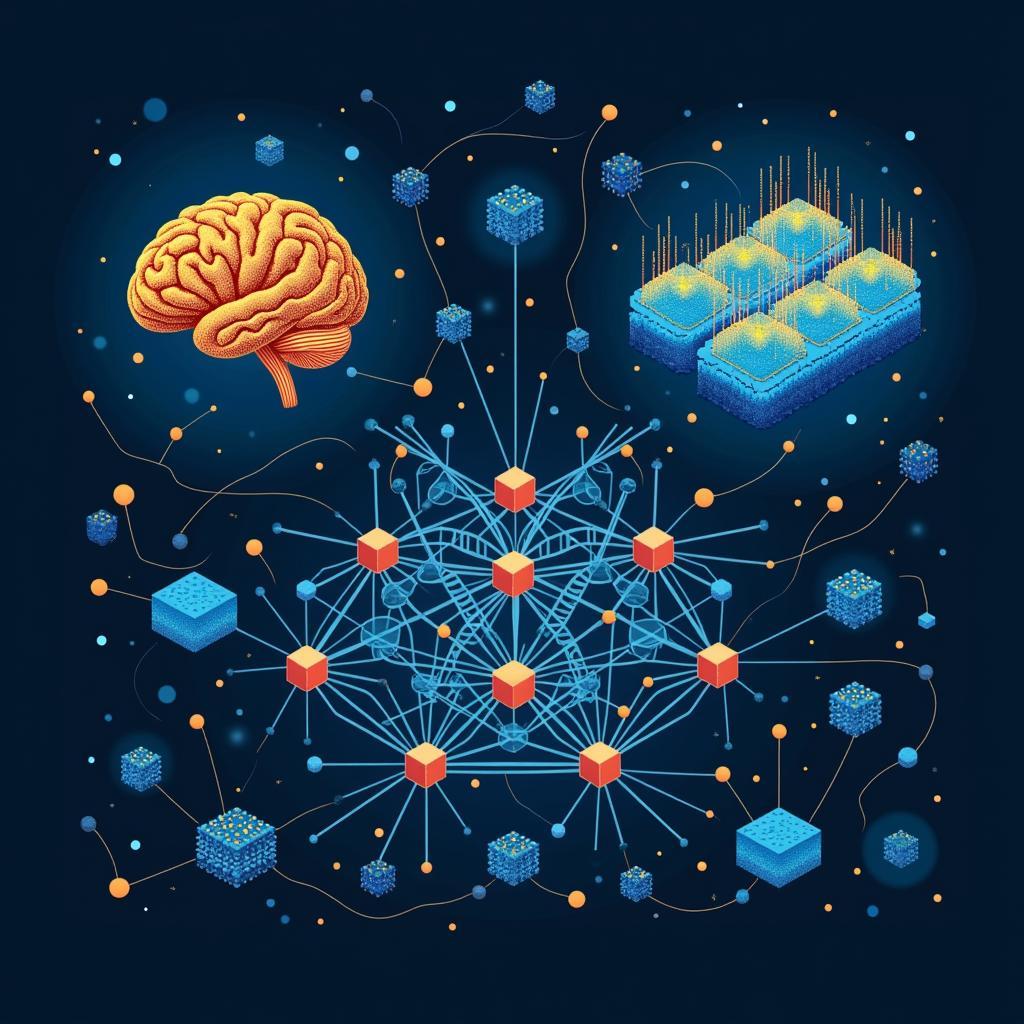

Advanced Simulation Techniques

The future of ase cut surface research lies in the development of more advanced simulation techniques. These include incorporating machine learning algorithms to accelerate calculations and improve accuracy. Additionally, developing methods to simulate dynamic processes on surfaces, such as diffusion and surface reconstruction, will provide even deeper insights into material behavior.

“Understanding the intricate relationship between surface structure and material properties is fundamental to materials science,” says Dr. Maria Sanchez, a leading researcher in computational materials science. “ASE cut surfaces offer a powerful tool for gaining this understanding and paving the way for the design of next-generation materials.”

Future Directions in ASE Cut Surface Research

Future Directions in ASE Cut Surface Research

Conclusion

The “ase cut surface” is a powerful concept in materials science, enabling researchers to investigate the fundamental properties of materials at the atomic level. By using ASE to create and analyze these surfaces, scientists can gain a deeper understanding of surface phenomena and design new materials with tailored properties. Further advancements in simulation techniques promise even greater insights into the complex world of surface science. Understanding these techniques is crucial for any researcher working with ASE and material surfaces.

FAQ

- What are Miller indices?

- How do I create a cut surface using ASE?

- What is surface energy and why is it important?

- How can ASE be used to simulate surface reactions?

- What are the challenges in simulating ase cut surfaces?

You might find further information regarding specific ASE applications, such as ASE 80 Schüco at ase 80 schüco or even explore resources related to ASE junk at ase junk.

For support, contact us at: Phone: 0369020373, Email: aseanmediadirectory@gmail.com, or visit us at: Thôn Ngọc Liễn, Hiệp Hòa, Bắc Giang, Việt Nam. We offer 24/7 customer service.