When a floating front brake caliper needs replacing, it’s more than just a simple part swap. It requires the expertise of a certified mechanic, ideally one with ASE Certification, to ensure the job is done right. But what exactly does this process entail and why is ASE Certification so important? This comprehensive guide delves into the intricacies of replacing a floating front brake caliper and highlights the significance of having an ASE Certified technician handle this crucial task.

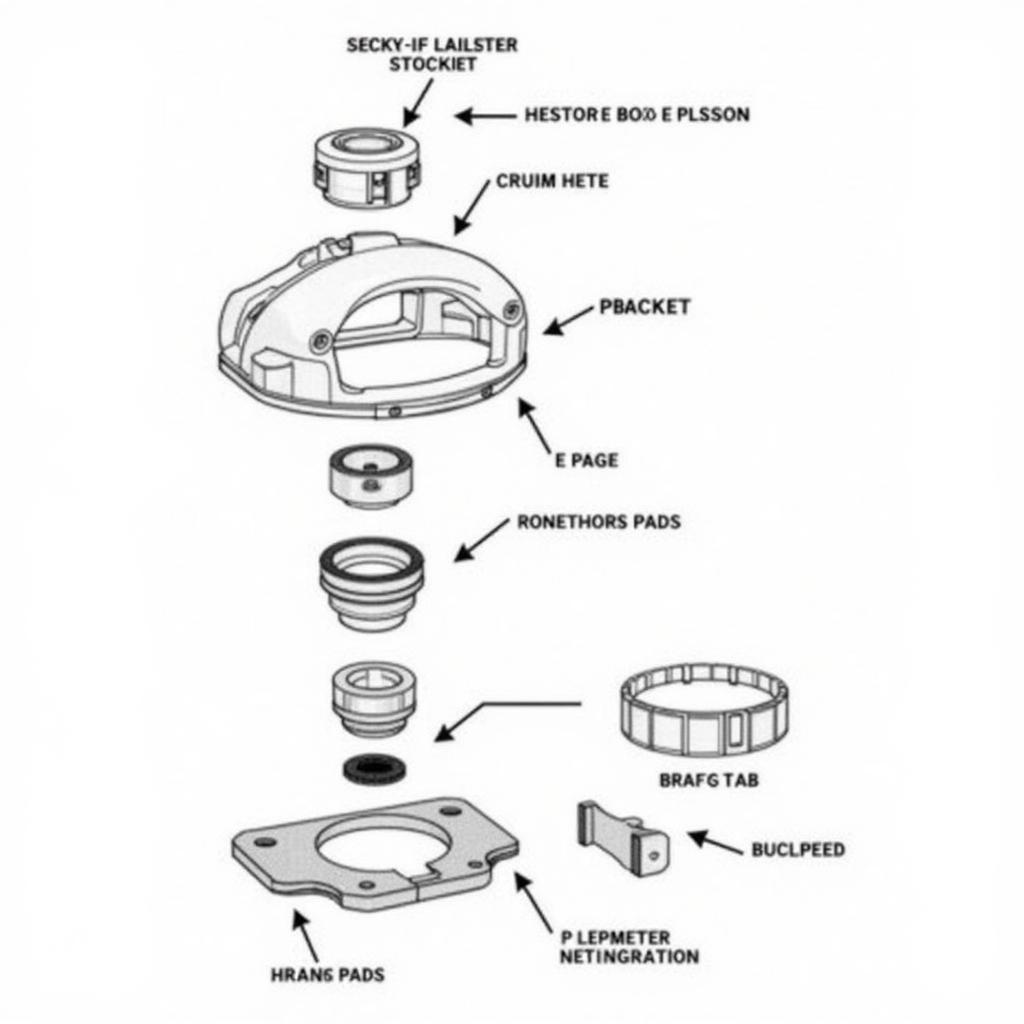

Components of a Floating Front Brake Caliper

Components of a Floating Front Brake Caliper

Understanding Floating Front Brake Calipers

Before we jump into the replacement process, it’s essential to understand what a floating front brake caliper is and how it functions. Unlike fixed calipers that utilize pistons on both sides, a floating caliper only has pistons on the inboard side. When you apply the brakes, hydraulic pressure from the master cylinder forces these pistons to push the brake pads against the rotor, generating the friction needed to stop your vehicle.

The Importance of ASE Certification

The ASE (Automotive Service Excellence) Certification is a benchmark of competency in the automotive repair industry. Mechanics who hold this certification have demonstrated their knowledge and skills through rigorous testing and practical experience.

“ASE Certification isn’t just a piece of paper,” says John Smith, a seasoned mechanic with over 20 years of experience. “It signifies a commitment to upholding industry standards and delivering high-quality service to customers.”

When an ASE Certified technician tackles a job like replacing a floating front brake caliper, you can rest assured that they possess the necessary skills to:

- Diagnose the issue accurately: Before replacing any parts, a thorough inspection is crucial to identify the root cause of the problem.

- Execute the repair correctly: This involves safely removing the old caliper, installing the new one with precision, bleeding the brake lines, and adjusting the caliper for optimal performance.

- Adhere to safety protocols: Brake repair involves inherent risks, and an ASE Certified technician is well-versed in the safety measures necessary to prevent accidents and ensure a safe working environment.

ASE Certified Mechanic Performing Brake Caliper Replacement

ASE Certified Mechanic Performing Brake Caliper Replacement

Steps Involved in Replacing a Floating Front Brake Caliper

Replacing a floating front brake caliper is a multi-step process that requires careful attention to detail. While the specifics might vary depending on the make and model of your vehicle, the general steps typically include:

- Securing the vehicle: The vehicle is safely lifted and secured on jack stands.

- Removing the wheel and tire: This provides access to the brake caliper assembly.

- Disconnecting the brake line: The brake line connected to the caliper is carefully disconnected.

- Detaching the caliper: The caliper is unbolted from the mounting bracket.

- Installing the new caliper: The new caliper is positioned and securely bolted in place.

- Connecting the brake line: The brake line is carefully connected to the new caliper.

- Bleeding the brakes: This crucial step removes any air bubbles from the brake lines, ensuring optimal braking performance.

- Reinstalling the wheel and tire: The wheel and tire are reinstalled, and the lug nuts are tightened to the manufacturer’s specifications.

- Testing the brakes: A thorough test drive is conducted to verify proper brake function and pedal feel.

When to Consider Caliper Replacement

Several signs might indicate a need for brake caliper replacement. If you experience any of the following symptoms, it’s crucial to have your brakes inspected by a qualified mechanic, preferably one with ASE Certification:

- Pulling to one side while braking: This could signal a sticking caliper piston.

- Spongy or soft brake pedal: A leak in the caliper or air in the brake lines can cause this.

- Unusual noises while braking: Grinding or squealing sounds often indicate worn-out brake pads or a caliper issue.

- Brake fluid leaks: Visible brake fluid leaks around the caliper require immediate attention.

Close-up of a Mechanic Inspecting a Brake Caliper

Close-up of a Mechanic Inspecting a Brake Caliper

Conclusion

Replacing a floating front brake caliper is a complex procedure that directly impacts your vehicle’s safety. Entrusting this task to an ASE Certified technician guarantees expertise, adherence to safety standards, and peace of mind knowing your brakes are in capable hands. Regular brake inspections and timely repairs are essential for maintaining optimal braking performance and ensuring your safety on the road.