The phrase “Ase Always On Tear Down” has been circulating in online forums, sparking curiosity and concern about the perceived fragility of products associated with ASE, a prominent semiconductor testing and packaging company with a significant presence in Southeast Asia. Is this perception accurate, or is it an overblown myth? This article delves into the topic, exploring the complexities of semiconductor testing, the role of ASE, and the reality behind product teardowns.

Understanding Semiconductor Testing and the Role of ASE

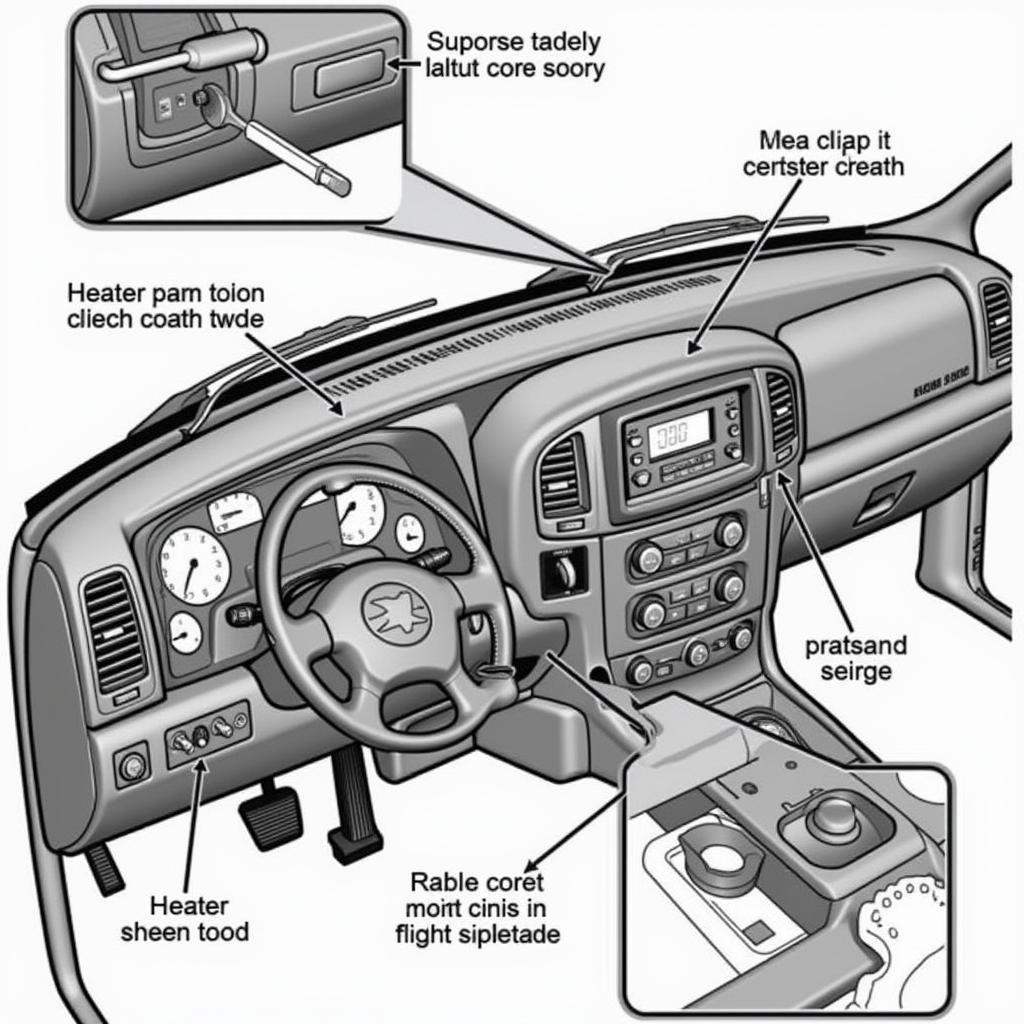

Semiconductor testing is a crucial stage in the manufacturing process. It ensures the quality and reliability of electronic components that power our modern world, from smartphones and laptops to cars and medical devices. ASE, as a key player in this field, performs a variety of tests to identify defects and ensure compliance with industry standards. These tests can range from simple electrical checks to complex analyses under various environmental conditions. ![]() Semiconductor Testing Process in Detail

Semiconductor Testing Process in Detail

This rigorous testing process often involves analyzing a sample of devices by “tearing them down” – deconstructing them to examine their internal structure and identify potential weaknesses. This is a standard practice across the semiconductor industry, not unique to ASE. While the term “tear down” might evoke images of destruction, it is a controlled and analytical process designed to improve product quality and performance. ase warranty reviews

The “Always On Tear Down” Misconception

The idea of “ASE always on tear down” likely stems from a misunderstanding of the testing process. While teardowns are a regular part of quality control, they are not perpetually conducted on every single device. It’s a targeted process applied to a representative sample to identify potential issues and improve the overall design and manufacturing process. The vast majority of devices shipped to consumers are never subjected to this kind of analysis.

Furthermore, advancements in non-destructive testing techniques are reducing the reliance on physical teardowns. Techniques like X-ray imaging and acoustic microscopy allow engineers to examine the internal structure of devices without physically disassembling them. This not only saves time and resources but also provides more comprehensive data. ase floor jack

What Does “ASE Always On Tear Down” Really Mean?

The phrase might be more accurately interpreted as a reflection of ASE’s commitment to continuous improvement. They are “always on” in the sense of constantly striving to enhance their testing methods, refine their processes, and deliver high-quality products. This dedication to quality involves ongoing analysis and evaluation, including strategic teardowns, to identify potential areas for improvement. ase brake pad replacement

“The pursuit of quality is a continuous journey, not a destination,” says Dr. Anya Sharma, a leading expert in semiconductor manufacturing. “Companies like ASE understand that constant vigilance and analysis, including teardowns, are essential for maintaining high standards and pushing the boundaries of innovation.”

Why is ASE so prominent in Southeast Asia?

ASE’s significant presence in Southeast Asia is attributed to several factors, including the region’s growing electronics manufacturing industry, favorable investment climate, and skilled workforce. This strategic location allows ASE to serve a diverse range of clients and contribute to the economic development of the region. ase makina yedek parça

Conclusion

The notion of “ASE always on tear down” is a mischaracterization of a crucial aspect of the semiconductor industry. Teardowns are a valuable tool for quality control and continuous improvement, not an indication of inherent product fragility. ASE’s commitment to rigorous testing is a testament to their dedication to delivering high-quality products that power our increasingly connected world. Understanding the nuances of semiconductor testing is key to appreciating the vital role ASE plays in the global technology landscape.

FAQs

- What is ASE?

- Why are semiconductor teardowns necessary?

- Are all ASE products torn down?

- What are the alternatives to physical teardowns?

- How does ASE contribute to the Southeast Asian economy?

- What is the significance of semiconductor testing?

- What are some common defects found during teardowns?

Have more questions? Need assistance? Please contact us: Phone: 0369020373, Email: [email protected]. Visit us at: Thôn Ngọc Liễn, Hiệp Hòa, Bắc Giang, Việt Nam. Our customer service team is available 24/7.