The ASE bump design process is crucial for ensuring reliable and efficient electrical connections in electronic devices. This guide will provide a detailed overview of the ASE bump design process, covering key aspects such as material selection, geometry optimization, and testing procedures. We’ll explore best practices and common challenges to help you create robust and high-performing bump designs.

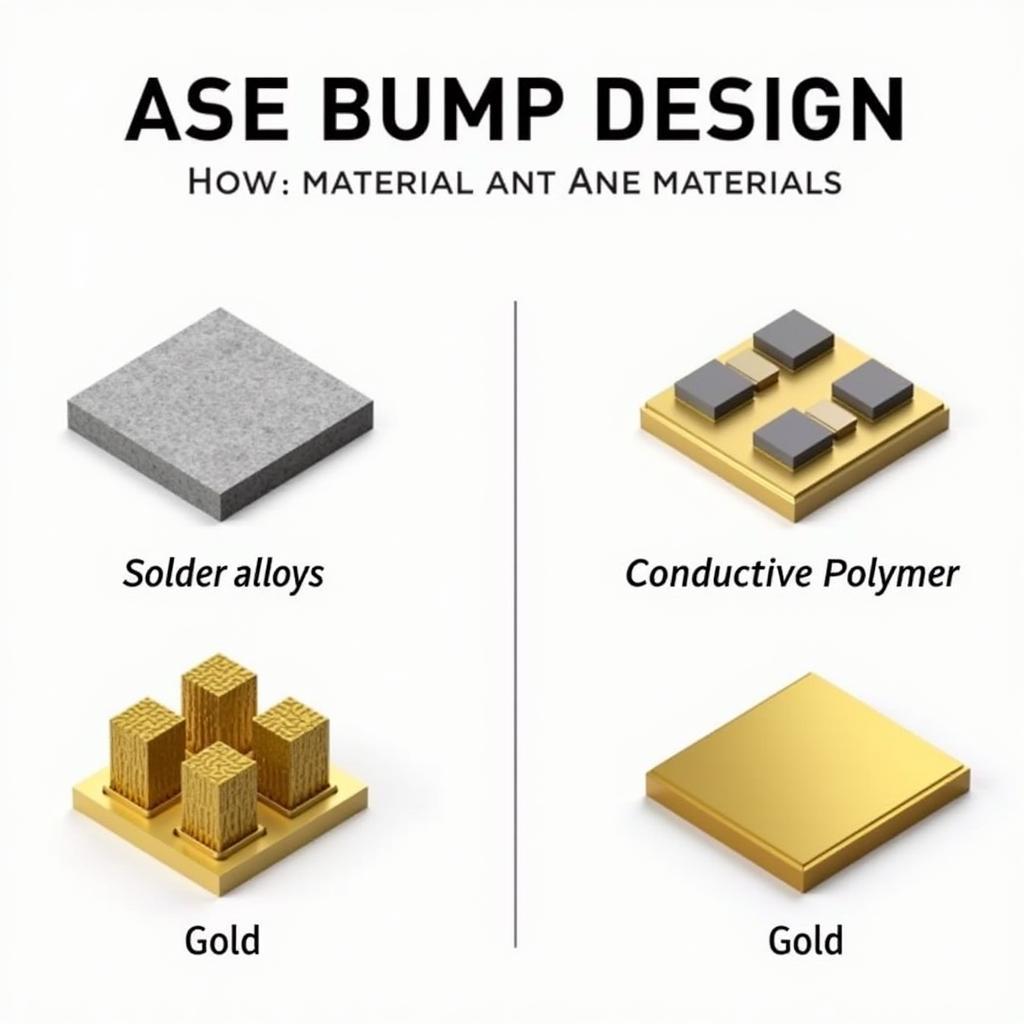

ASE Bump Design Materials: A Close-up View

ASE Bump Design Materials: A Close-up View

Understanding the Importance of ASE Bump Design

ASE (Advanced Semiconductor Engineering) bump technology is essential for connecting integrated circuits (ICs) to other components on a printed circuit board (PCB). A well-designed bump ensures optimal electrical and thermal performance, impacting the overall reliability and lifespan of the device. Factors like bump size, shape, and material composition directly influence signal integrity, power efficiency, and mechanical stability. ase power bank

Key Considerations in ASE Bump Design

Several crucial factors need to be considered during the ASE bump design process:

- Material Selection: Selecting the appropriate bump material is critical for achieving desired electrical and thermal conductivity, as well as mechanical strength. Common materials include lead-free solder alloys, conductive polymers, and gold.

- Bump Geometry: The bump’s shape and size significantly impact its electrical and mechanical performance. Factors like bump height, diameter, and pitch need to be optimized for specific application requirements.

- Under Bump Metallization (UBM): The UBM layer acts as a barrier and adhesion layer between the bump and the IC pad. Choosing the right UBM material and thickness is essential for ensuring reliable interconnection.

ASE Bump Design Process: A Step-by-Step Guide

The ASE bump design process typically involves the following steps:

- Substrate Preparation: The substrate, typically a silicon wafer, is cleaned and prepared for the subsequent deposition processes.

- UBM Deposition: The UBM layer is deposited onto the substrate using techniques like sputtering or evaporation.

- Bump Formation: The bump material is deposited onto the UBM layer using techniques like electroplating or solder reflow.

- Reflow and Assembly: The bumped die is then attached to the PCB using reflow soldering.

- Testing and Inspection: The assembled device undergoes rigorous testing to ensure the quality and reliability of the bump connections. ase suspension and steering kindle

Common Challenges in ASE Bump Design

While ASE bump technology offers significant advantages, some challenges need to be addressed:

- Warpage: Differences in the coefficient of thermal expansion (CTE) between the die and the substrate can lead to warpage during temperature cycling, potentially causing bump failures.

- Solder Joint Reliability: Ensuring the long-term reliability of solder joints under various operating conditions is crucial.

- Cost Optimization: Balancing performance requirements with cost considerations is an ongoing challenge. 2024 macbook pro tough c ase

Conclusion

A well-executed ASE bump design is essential for ensuring the performance and reliability of electronic devices. By carefully considering material selection, geometry optimization, and testing procedures, engineers can create robust and efficient interconnections. Adhering to best practices and addressing common challenges will lead to optimized ASE bump designs that meet the demands of modern electronics. ase transmission covington tn. Remember that a thorough understanding of the [Ase Bump Design Guide] is key to success in this field.

FAQ

- What are the most common materials used in ASE bump design?

- How does bump geometry affect signal integrity?

- What are the key challenges in ASE bump design?

- What is the role of UBM in ASE bump technology?

- What are the different testing methods used to evaluate bump reliability?

- How can warpage be mitigated in ASE bump design?

- What are the cost considerations in ASE bump design? list of ase certifications

When you need support, please contact Phone Number: 0369020373, Email: aseanmediadirectory@gmail.com Or visit the address: Ngoc Lien Village, Hiep Hoa, Bac Giang, Vietnam. We have a 24/7 customer care team.