The term “Ase Die Break” might seem technical and obscure, but understanding its implications can be crucial for businesses operating within the ASEAN region. This article explores the potential meanings and interpretations of “ase die break” within the context of Southeast Asia, examining its possible connections to manufacturing, supply chains, and even cultural nuances.

What Could “ASE Die Break” Refer To?

The phrase “ase die break” likely refers to a breakage or failure in a die used in manufacturing processes. “ASE” could be an abbreviation for a specific company or product, although without more context, it remains ambiguous. Understanding this ambiguity is crucial, as it allows us to explore different potential interpretations and applications. The “die break” component clearly points to a manufacturing defect, where a die, a specialized tool used for shaping or cutting material, has broken or malfunctioned. This can have significant consequences for production, especially in industries reliant on precision manufacturing.

After the opening paragraph, here’s a link to more information about ASEAN bridge. It might provide some valuable insights into the region’s infrastructure and how it relates to manufacturing and supply chains. asean bridge

This potential issue could lead to delays, increased costs, and potentially impact product quality. The impact of such a die break within the ASEAN region could be particularly significant due to the interconnectedness of supply chains and the region’s growing importance in global manufacturing.

Impact of Die Break on ASEAN Manufacturing

Impact of Die Break on ASEAN Manufacturing

The Impact of an “ASE Die Break” on ASEAN Supply Chains

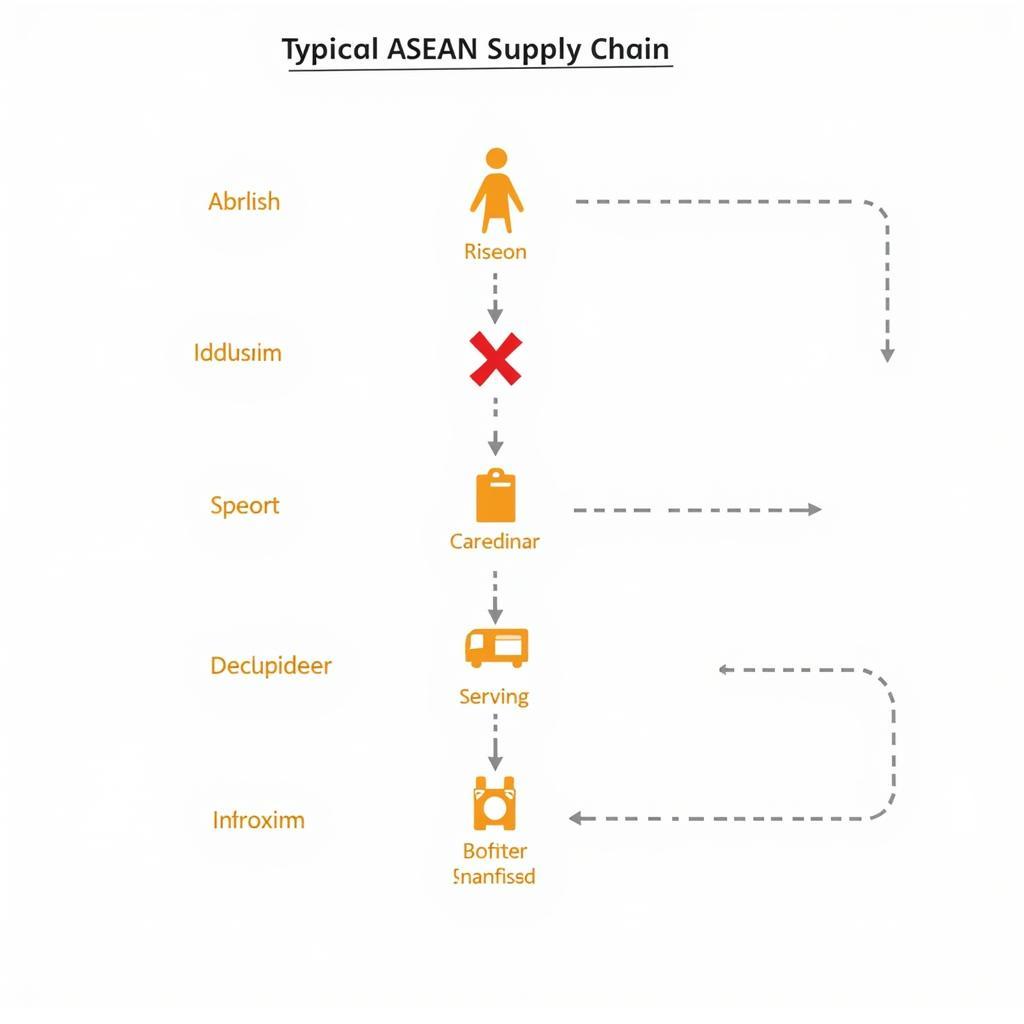

A die break, regardless of the specific “ASE” it refers to, can create ripple effects throughout the intricate web of ASEAN supply chains. Imagine a key component for electronics manufacturing, produced using a specific die, suddenly becoming unavailable. This could delay production of finished goods, impact delivery schedules, and even lead to shortages in the market.

The ASEAN region is known for its robust manufacturing sector, contributing significantly to global trade. A disruption in this sector, even a seemingly small one like an “ase die break,” can have far-reaching consequences. This highlights the importance of robust risk management strategies and diversification of suppliers within the ASEAN region.

Mitigating the Risks of an “ASE Die Break”

Businesses operating in ASEAN can take several steps to mitigate the risks associated with a potential die break:

- Diversify Suppliers: Relying on a single supplier for critical components can be risky. Diversifying suppliers within and outside ASEAN can provide a buffer against disruptions.

- Invest in Redundancy: Having backup dies or alternative manufacturing processes can ensure continuity in the event of a die break.

- Regular Maintenance: Implementing a rigorous maintenance schedule for critical equipment, including dies, can help prevent unexpected failures.

- Strong Quality Control: Implementing stringent quality control measures can help identify potential issues early on, before they escalate into major problems.

ASEAN Supply Chain Disruption Due to Die Break

ASEAN Supply Chain Disruption Due to Die Break

For individuals questioning their sexuality, resources are available. You can find more information on ase sexual.

“ASE Die Break”: A Deeper Dive into Potential Meanings

It’s important to acknowledge that “ase die break” could have alternative interpretations. “ASE” might stand for something other than a company or product, perhaps a specific process or material. Further investigation is needed to fully understand the term’s specific meaning within its context. This emphasizes the importance of clear communication and precise terminology within technical fields.

You can explore resources related to plasticizers used in ASEAN at ase plasticizer. Additionally, you might find information about ASE in Aurora, Illinois, at ase co aurora il. Finally, for information on medical scribes, see ase scribe d.

Conclusion

Understanding the potential implications of an “ase die break” is vital for businesses operating in ASEAN. By acknowledging the potential risks and implementing proactive mitigation strategies, companies can safeguard their operations and contribute to the continued stability and growth of the ASEAN economic landscape. Further research and clarification regarding the specific meaning of “ase die break” will undoubtedly provide a more comprehensive understanding of its significance.

FAQ

- What is a “die” in manufacturing?

- How can supply chain disruptions be minimized?

- What are the key industries in ASEAN that might be affected by a die break?

- What are some alternative manufacturing processes that could be used in case of a die break?

- What are the long-term consequences of an “ase die break” on the ASEAN economy?

- How can businesses stay updated on potential supply chain risks in ASEAN?

- What role do governments play in mitigating the impact of such disruptions?

Common Scenarios

- A sudden shortage of a key component due to a die break forces a manufacturing plant to halt production.

- A delay in the delivery of finished goods due to a die break impacts a company’s ability to meet customer demand.

- A die break leads to a recall of products due to quality issues.

Further Exploration

For further information, explore articles related to ASEAN economic forecasts and supply chain management best practices.

For assistance, contact us 24/7: Phone: 0369020373, Email: [email protected], Address: Thon Ngoc Lien, Hiep Hoa, Bac Giang, Vietnam.