The term “Ase Die Crack” might seem cryptic at first glance, sparking curiosity and raising questions. This article delves into the meaning and implications of this phrase, exploring its potential connections to various fields from manufacturing to software development, and considering the broader context of ASEAN’s dynamic economic landscape.  Manufacturing Defect Leading to Ase Die Crack

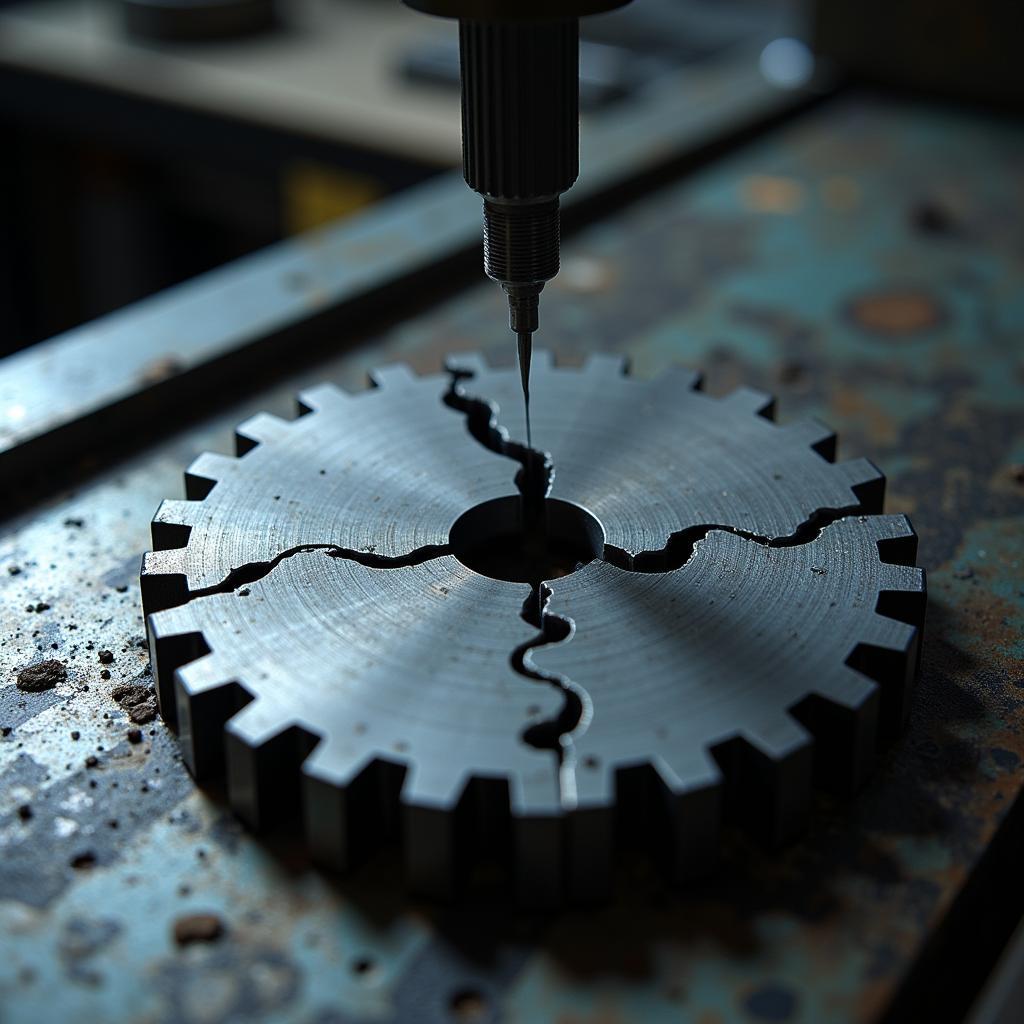

Manufacturing Defect Leading to Ase Die Crack

What Does “Ase Die Crack” Actually Mean?

While the precise meaning of “ase die crack” can be elusive without specific context, it likely refers to a crack in a die, a specialized tool used in manufacturing processes. Dies are essential for shaping or cutting materials, especially in mass production. A cracked die can lead to production errors, compromised product quality, and financial losses. como se ase un flan

The Impact of “Ase Die Crack” on Manufacturing

In the context of ASEAN’s burgeoning manufacturing sector, “ase die crack” highlights the importance of quality control and precision engineering. A single cracked die can disrupt production lines and impact delivery schedules, affecting everything from automotive parts to consumer electronics. This underscores the need for robust quality assurance measures throughout the manufacturing process.

Beyond Manufacturing: Exploring Other Interpretations

“Ase die crack” could also be interpreted metaphorically, representing vulnerabilities or weaknesses within a system or process. For instance, in software development, it might allude to a critical flaw in code that could lead to system crashes or security breaches. ase turbo manifold Similarly, in the financial world, it could symbolize a weakness in a market or investment strategy that could result in significant losses.

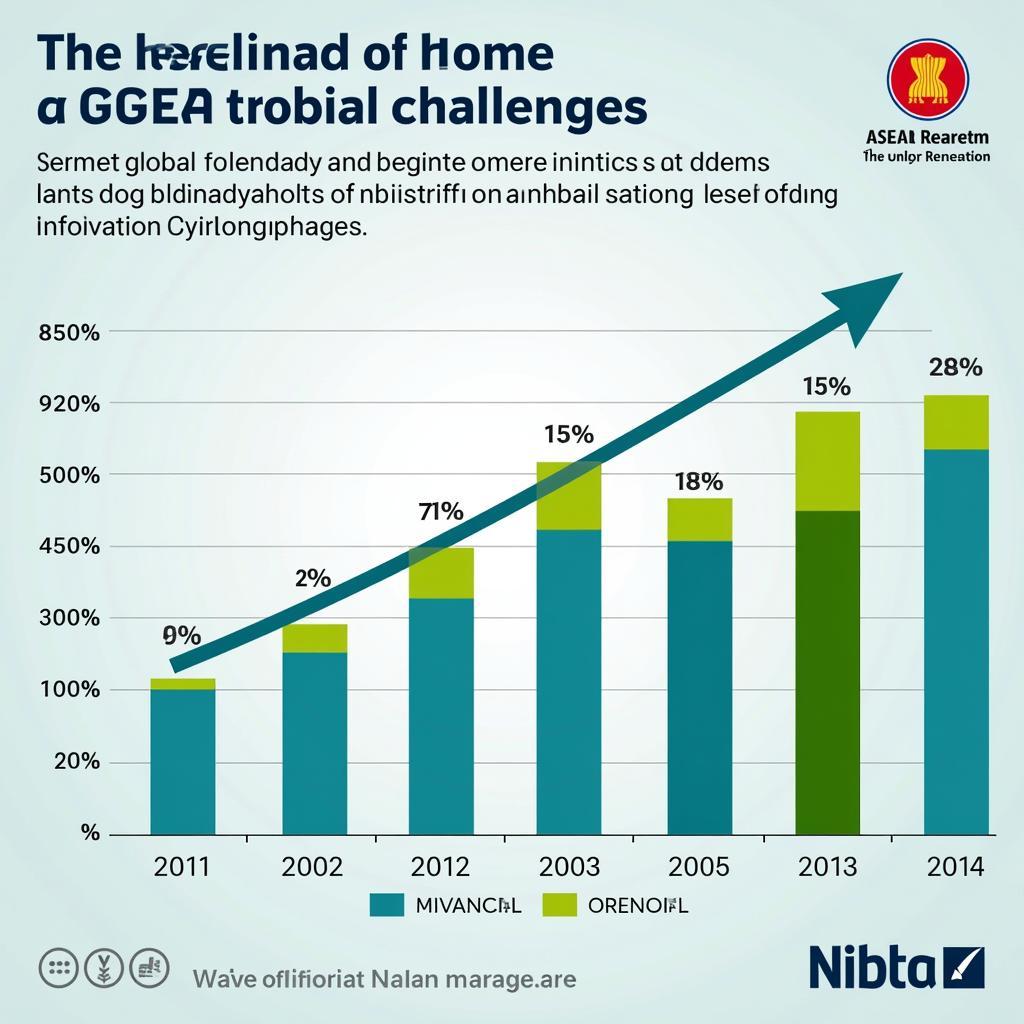

The ASEAN Context: Challenges and Opportunities

Within the dynamic context of ASEAN, “ase die crack” represents a broader challenge of maintaining quality and resilience in the face of rapid economic growth. As ASEAN nations strive to become global manufacturing hubs and technological innovators, addressing potential “cracks” in their systems and processes is crucial for sustainable development. ase plasticizer

Addressing “Ase Die Crack”: Solutions and Strategies

Preventing and addressing “ase die crack” requires a multi-faceted approach. In manufacturing, this involves investing in advanced die materials, implementing rigorous quality control procedures, and adopting predictive maintenance strategies. In other contexts, it necessitates thorough risk assessment, robust testing protocols, and continuous improvement measures.

Investing in Innovation and Technology

ASEAN nations are increasingly investing in research and development, fostering innovation, and adopting cutting-edge technologies to mitigate risks and enhance resilience. This proactive approach is essential for navigating the complexities of the global marketplace and ensuring long-term competitiveness. asea bushings gob 250 o-ring

Conclusion: Building a Stronger, More Resilient ASEAN

“Ase die crack,” whether interpreted literally or metaphorically, serves as a reminder of the importance of vigilance and proactive measures in ensuring quality, resilience, and sustainable growth within ASEAN. By addressing potential vulnerabilities and investing in innovation, ASEAN nations can build a stronger, more robust foundation for future success. como se ase el flan  ASEAN Economic Growth and Resilience

ASEAN Economic Growth and Resilience

FAQ:

- What is the most common cause of die cracks?

- How can die cracks be detected early?

- What are the consequences of using a cracked die?

- What are the latest technologies for preventing die cracks?

- How can ASEAN businesses improve their quality control processes?

- What is the role of innovation in addressing “ase die crack”?

- What are the long-term implications of “ase die crack” for ASEAN’s economic development?

Need assistance? Contact us 24/7: Phone: 0369020373, Email: aseanmediadirectory@gmail.com, Address: Thon Ngoc Lien, Hiep Hoa, Bac Giang, Vietnam.