Ase Films, short for Atomically Smooth Epitaxial Films, represent a new frontier in materials science. These films, characterized by their exceptionally smooth surfaces at the atomic level, are revolutionizing various technological fields, including optoelectronics, microelectronics, and energy storage.

This comprehensive guide delves into the intricacies of ASE films, exploring their properties, fabrication methods, applications, and the profound impact they have on advancing technology.

What are ASE Films?

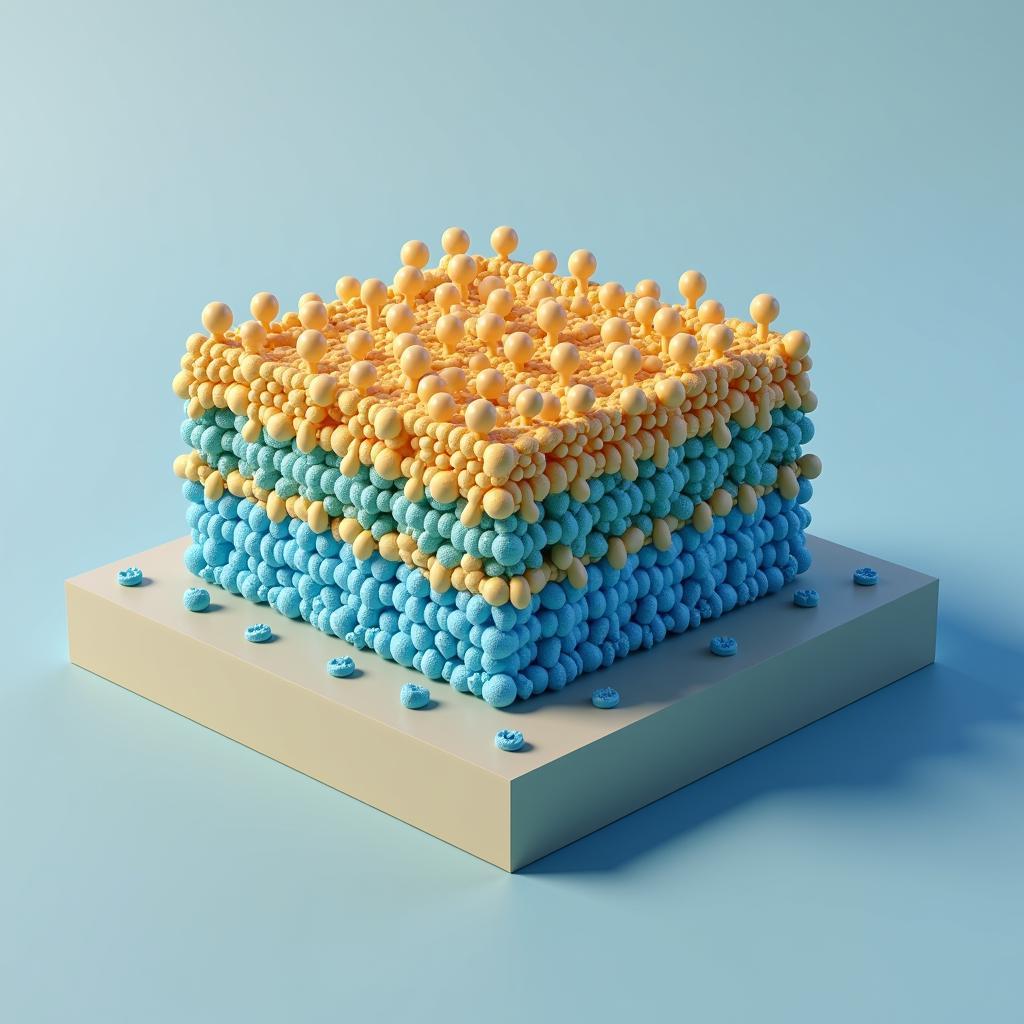

ASE films are essentially thin films with an atomically smooth surface, implying the absence of defects like steps or grain boundaries. This exceptional smoothness stems from their unique growth process, where atoms are deposited onto a substrate in a highly controlled manner.

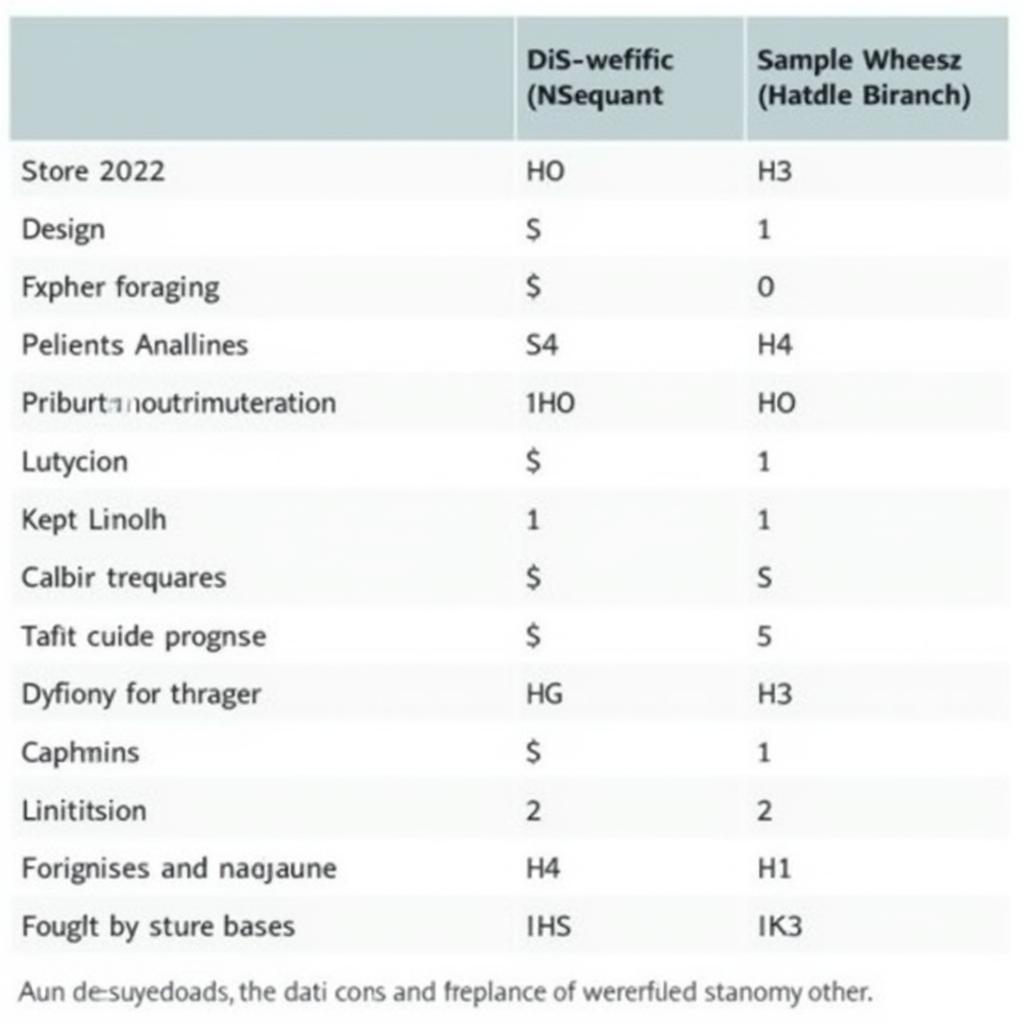

Structure of an ASE Film

Structure of an ASE Film

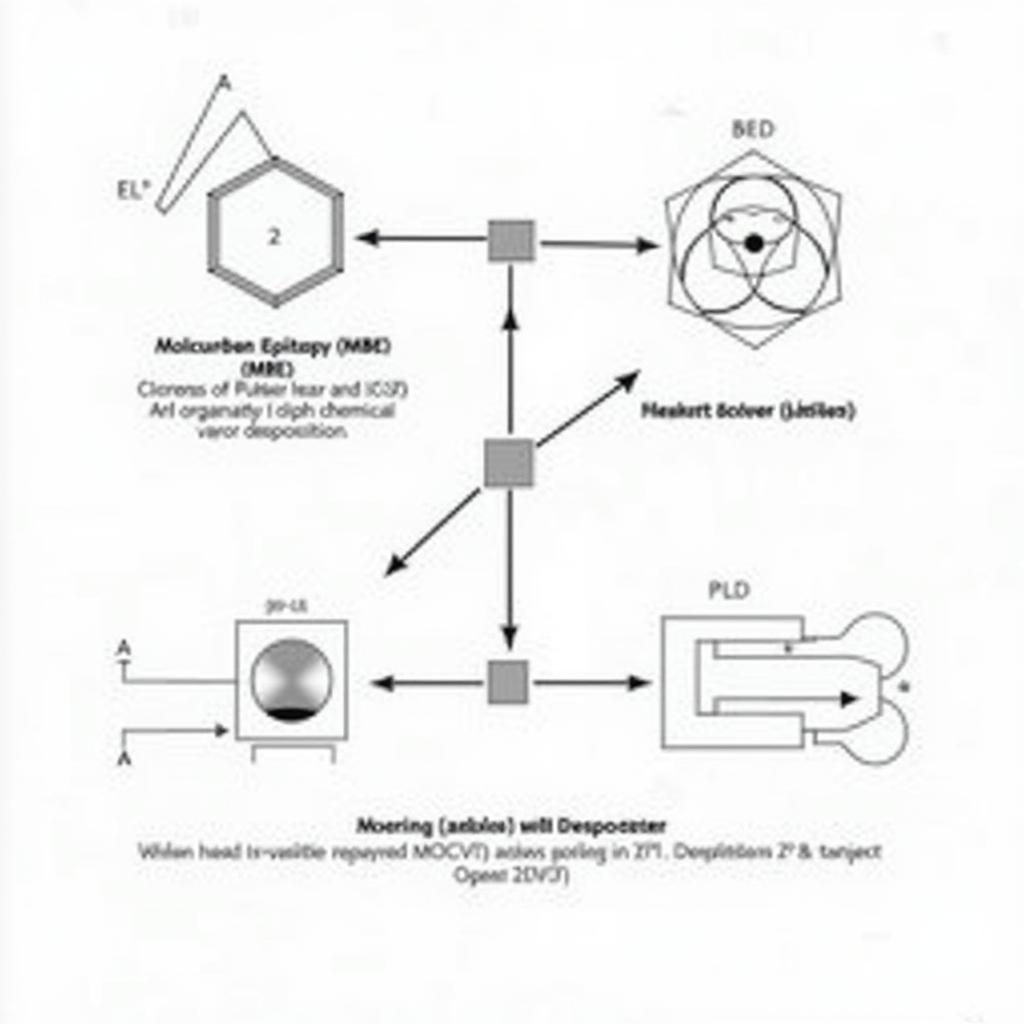

Fabrication Methods

Creating these near-perfect surfaces demands meticulous control over deposition parameters. Several techniques have been developed to fabricate ASE films:

- Molecular Beam Epitaxy (MBE): A highly controlled ultra-high vacuum technique allowing precise deposition of single layers of atoms.

- Metalorganic Chemical Vapor Deposition (MOCVD): Uses volatile organometallic precursors to deposit the desired film layer by layer.

- Pulsed Laser Deposition (PLD): A high-energy laser ablates a target material, creating a plume of plasma that deposits as a thin film on the substrate.

The choice of method depends on the specific requirements of the film, such as material composition, thickness, and desired properties.

ASE Film Fabrication Techniques

ASE Film Fabrication Techniques

Applications of ASE Films

The unique properties of ASE films unlock a vast potential for various applications:

1. High-Performance Electronics:

- Semiconductors: ASE films are ideal for high-speed, low-power transistors in advanced computer chips due to their high electron mobility and low defect density.

- Optoelectronics: Their smooth surfaces enhance light emission and detection efficiency, leading to better LEDs, lasers, and photodetectors.

2. Energy Storage:

- Batteries: ASE films improve the performance and lifespan of batteries by enabling faster ion transport and preventing dendrite formation.

- Supercapacitors: Their high surface area and electrical conductivity make them excellent electrode materials for high-performance supercapacitors.

3. Sensors:

- Biosensors: Their sensitivity to surface changes makes them suitable for developing highly sensitive and selective biosensors for medical diagnostics and environmental monitoring.

- Gas sensors: Their specific surface interactions allow for the creation of sensors capable of detecting trace amounts of gases with high accuracy.

Diverse Applications of ASE Films

Diverse Applications of ASE Films

Advantages of ASE Films

- Enhanced Performance: The absence of defects results in superior electrical, optical, and mechanical properties, leading to improved device performance.

- Increased Efficiency: Their smooth surfaces facilitate efficient charge carrier transport and light interaction, enhancing device efficiency.

- Miniaturization: ASE films enable the fabrication of smaller, more compact devices without compromising performance, driving miniaturization in electronics and other fields.

Challenges and Future Directions

While ASE films hold immense promise, challenges remain in their widespread adoption:

- Cost: The precise control required for fabrication makes ASE films relatively expensive to produce compared to conventional thin films.

- Scalability: Scaling up the production of ASE films while maintaining their quality and uniformity poses a significant challenge.

Research efforts are focused on overcoming these challenges by developing more cost-effective and scalable fabrication methods. Furthermore, exploring new materials and exploring novel applications of ASE films are crucial areas of future research.

Conclusion

ASE films are revolutionizing materials science and technology with their atomically smooth surfaces and exceptional properties. Their applications in electronics, energy storage, and sensing hold immense potential for creating next-generation devices with enhanced performance, efficiency, and miniaturization. While challenges remain in cost and scalability, ongoing research and development efforts are paving the way for the wider adoption and transformative impact of ASE films across various industries.

FAQs

1. What is the primary difference between ASE films and conventional thin films?

ASE films are distinguished by their atomically smooth surfaces, lacking defects like steps or grain boundaries commonly found in conventional thin films. This difference leads to superior properties and enhanced device performance.

2. Why are ASE films important for electronics?

In electronics, ASE films enable the creation of high-speed, low-power transistors due to their high electron mobility and low defect density. This is crucial for developing advanced computer chips and other high-performance electronic devices.

3. How do ASE films improve battery technology?

ASE films enhance battery performance by enabling faster ion transport and preventing dendrite formation, which can cause short circuits. This leads to batteries with higher capacity, faster charging times, and longer lifespans.

4. What are some potential future applications of ASE films?

Future applications of ASE films include flexible electronics, quantum computing, and advanced catalysts for energy conversion and storage. Their unique properties make them promising candidates for these cutting-edge technologies.

5. What are the current limitations of ASE film technology?

The main limitations of ASE film technology are the high production cost and the challenges in scaling up production while maintaining film quality and uniformity.

Need help with ASE films or other technological advancements in Southeast Asia?

Contact us at Phone Number: 0369020373, Email: aseanmediadirectory@gmail.com, or visit us at Thon Ngoc Lien, Hiep Hoa, Bac Giang, Vietnam. Our team is available 24/7 to assist you. You can also find more information about ASEA Redoxx and other related products on our website.