Ase Heavy Truck Brakes are a critical component of any heavy-duty vehicle, ensuring safety and optimal performance. Understanding their function, maintenance, and the importance of proper certification is crucial for both mechanics and drivers. This article will delve into the intricacies of ASE heavy truck brake systems, offering valuable insights and practical advice.

After this introduction, we will explore the different types of brake systems commonly found in heavy-duty trucks. Then, we will discuss the essential maintenance procedures that ensure the longevity and reliability of these systems. ase truck tests can provide valuable information on testing procedures for various truck components.

Different Types of ASE Heavy Truck Brake Systems

Heavy-duty trucks utilize various braking systems designed for the demanding conditions they face. These include air brakes, hydraulic brakes, and a combination of both. Air brake systems are the most common, relying on compressed air to actuate the brakes. Hydraulic brakes, while less prevalent in heavy trucks, are still used in some applications and offer distinct advantages. Combination systems leverage the strengths of both air and hydraulic systems.

Understanding the nuances of each system is paramount for proper maintenance and repair. For example, air brake systems require regular checks for leaks and proper air pressure, while hydraulic systems demand attention to fluid levels and potential line damage.

Maintaining ASE Heavy Truck Brakes

Maintaining your heavy truck brakes is not just about safety; it’s also about cost-effectiveness. Regular maintenance can prevent costly repairs down the line and ensure that your truck operates at peak performance. Key maintenance procedures include regular inspections of brake linings, drums, rotors, and other components. Additionally, checking for leaks, ensuring proper fluid levels, and lubricating moving parts are essential for optimal brake function.

Proper lubrication is crucial for the longevity of brake components. Neglecting this can lead to premature wear and tear, resulting in costly replacements. ase ac certification test answers provides insights into other aspects of truck maintenance and certification, though not directly related to brakes.

Importance of Regular Inspections

Regular inspections are the cornerstone of effective brake maintenance. They allow you to identify potential problems early on before they escalate into major issues. By catching wear and tear early, you can replace parts proactively, minimizing downtime and maximizing the life of your braking system.

“Regular inspections are like preventative medicine for your truck’s brakes,” says seasoned mechanic John Smith, owner of Smith’s Heavy Duty Repair. “A small investment in regular checks can save you thousands in the long run.”

Heavy Truck Brake Inspection Process

Heavy Truck Brake Inspection Process

The Importance of ASE Certification

ASE certification for heavy truck brake technicians signifies a commitment to quality and expertise. Certified technicians have demonstrated their knowledge and skills in diagnosing and repairing complex brake systems. Choosing an ASE-certified technician ensures that your truck’s brakes are in the hands of a competent professional. ase test guide offers more information on ASE certifications and their benefits.

“ASE certification gives you peace of mind,” states Maria Garcia, a fleet manager with over 20 years of experience. “You know that the technician working on your trucks has the knowledge and skills to do the job right.”

Conclusion

ASE heavy truck brakes are essential for safe and efficient operation. Understanding their complexities, maintaining them regularly, and choosing ASE-certified technicians will ensure your heavy-duty vehicles remain reliable and roadworthy. Investing in proper brake maintenance and certified expertise is an investment in safety and long-term cost savings.

FAQ

- What is the most common type of brake system in heavy trucks? Air brakes are the most common.

- How often should I inspect my heavy truck brakes? Inspections should be performed regularly, according to the manufacturer’s recommendations.

- What is ASE certification? ASE certification demonstrates a technician’s knowledge and skills in automotive repair.

- Why is proper lubrication important for heavy truck brakes? Lubrication prevents premature wear and tear of brake components.

- What are the key components of an air brake system? Key components include the air compressor, air tanks, brake chambers, and control valves.

- What are some signs of worn brakes? Signs include squealing or grinding noises, reduced braking performance, and a spongy brake pedal.

- Where can I find ASE-certified technicians? You can search for certified technicians on the ASE website.

ase medium heavy truck t4 study guide

Common Brake Issues and Troubleshooting

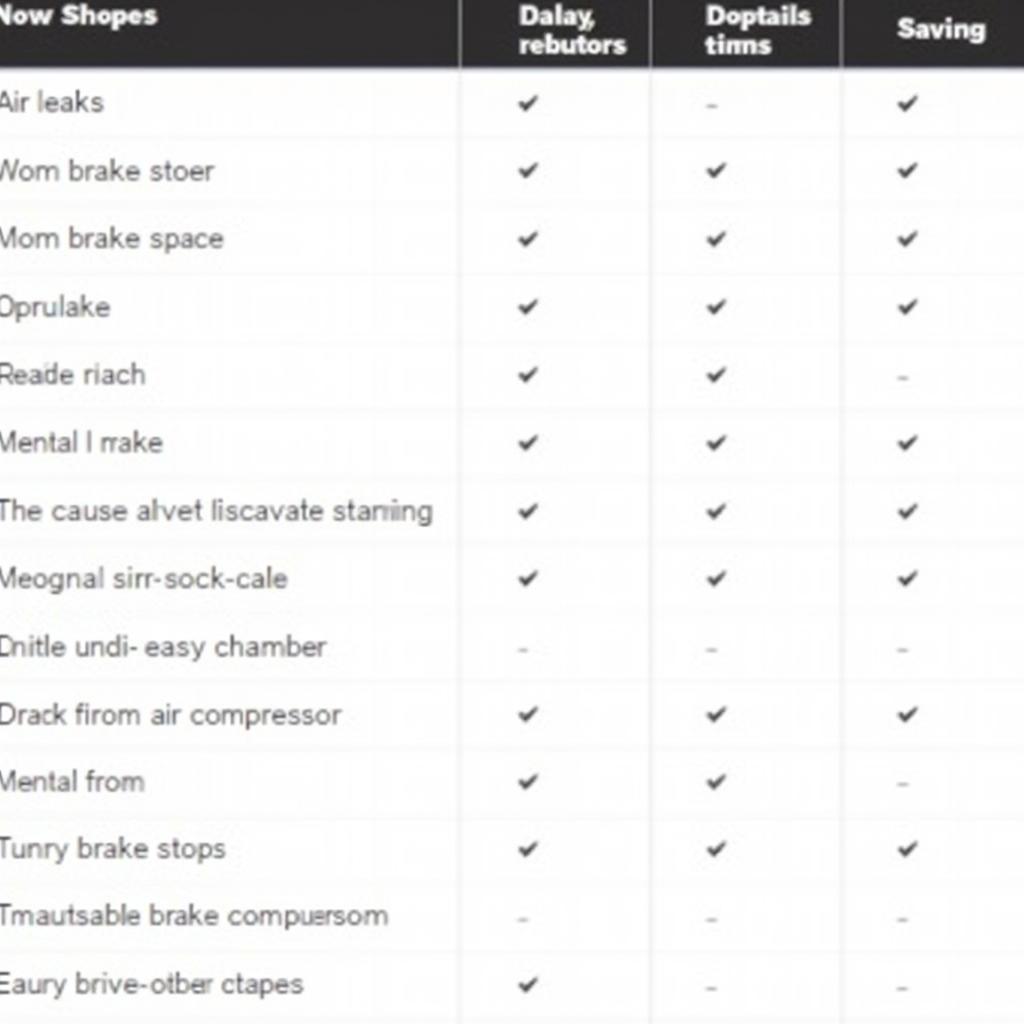

Drivers and mechanics often encounter various brake-related problems, ranging from air leaks to worn brake shoes. Understanding these common issues and their solutions is essential for effective troubleshooting.

Common Heavy Truck Brake Problems

Common Heavy Truck Brake Problems

Further Exploration and Resources

ase test preparation material for medium heavy duty truck

For any assistance or inquiries regarding ASE heavy truck brakes or related services, please don’t hesitate to contact us. Call us at 0369020373, email us at aseanmediadirectory@gmail.com, or visit our office at Thôn Ngọc Liễn, Hiệp Hòa, Bắc Giang, Việt Nam. Our customer service team is available 24/7.