The year 2015 saw growing concerns about the environmental impact of refrigerants. The “Ase Refrigerant Recovery And Recycling Answers 2015” became a hot topic for technicians and industry professionals seeking clarity on best practices. While time has passed, the core principles remain relevant. This article delves into the significance of refrigerant recovery and recycling, focusing on the key questions and answers that shaped the conversation in 2015.

Why Was Refrigerant Recovery a Hot Topic in 2015?

The year 2015 marked a turning point in environmental awareness. The detrimental effects of ozone depletion and climate change were becoming increasingly evident. Refrigerants, particularly hydrochlorofluorocarbons (HCFCs) like R-22, were identified as major contributors to these issues.

The global push to phase out ozone-depleting substances under the Montreal Protocol put a spotlight on refrigerant recovery and recycling. In the United States, the Environmental Protection Agency (EPA) implemented regulations requiring technicians to be certified in proper refrigerant handling practices. This included recovering refrigerant from systems before disposal or repair to prevent it from escaping into the atmosphere.

What Were the Key ASE Refrigerant Recovery and Recycling Answers in 2015?

1. What is Refrigerant Recovery?

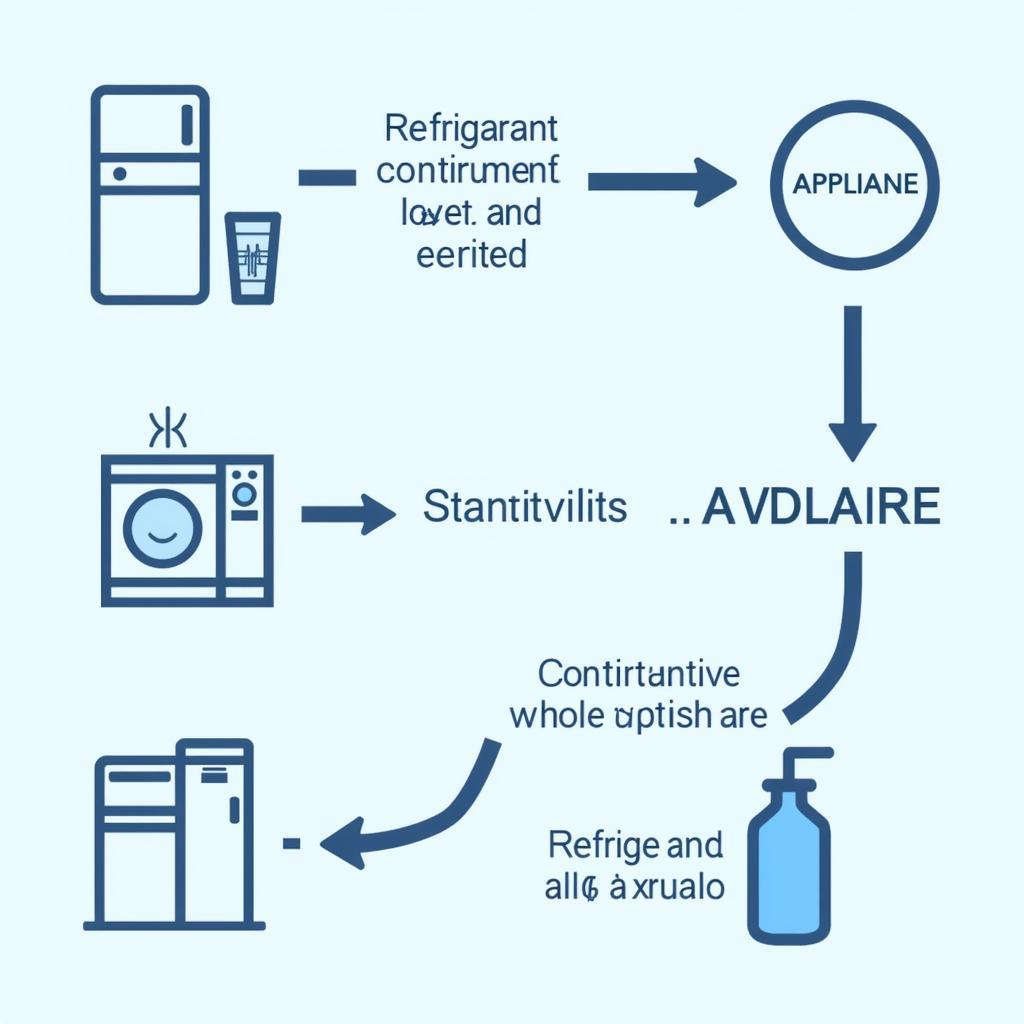

Refrigerant recovery refers to the process of extracting refrigerant from an appliance and storing it in an external container. This prevents the refrigerant from being released into the atmosphere.

2. Why is Refrigerant Recovery Important?

Recovering refrigerant protects the ozone layer and mitigates climate change. Refrigerants contain chlorine and fluorine atoms that, when released, contribute to the depletion of the ozone layer, our planet’s protective shield against harmful UV radiation. Additionally, refrigerants are potent greenhouse gases, trapping heat in the atmosphere and contributing to global warming.

Refrigerant Recycling Process in 2015

Refrigerant Recycling Process in 2015

3. What is the Difference Between Recovery and Recycling?

Recovery involves extracting refrigerant and storing it. Recycling goes a step further, cleaning and purifying the recovered refrigerant to meet industry standards for reuse.

4. What Are the Different Types of Refrigerant Recovery Equipment?

In 2015, technicians commonly used recovery machines designed to handle specific types of refrigerants, such as CFCs, HCFCs, and HFCs. These machines varied in size and recovery rate, catering to different applications.

5. What Are the Regulations Surrounding Refrigerant Recovery?

The EPA’s Section 608 of the Clean Air Act outlines the regulations governing refrigerant handling. This includes requirements for technician certification, recovery equipment standards, and record-keeping for refrigerant transactions.

6. What is the Role of ASE Certification in Refrigerant Recovery?

The National Institute for Automotive Service Excellence (ASE) offers certification exams for automotive technicians, including a dedicated exam for refrigerant recovery and recycling. While not mandated by the EPA, ASE certification demonstrates a technician’s knowledge and commitment to industry best practices, including proper refrigerant handling.

7. How Do I Choose the Right Refrigerant Recovery Equipment?

Choosing the right equipment depends on factors like the type of refrigerant used, the size of the system, and the frequency of use. Consulting with industry experts and suppliers can help determine the most suitable equipment for specific needs.

Conclusion

The “ASE refrigerant recovery and recycling answers 2015” provided valuable insights into the importance of responsible refrigerant management. Though 2015 marked a pivotal year, the principles and practices remain relevant today. By understanding the significance of refrigerant recovery and recycling, embracing technological advancements, and adhering to industry regulations, we can minimize the environmental impact of refrigerants and contribute to a more sustainable future. For more information on ASE EPA 609 certification, visit ase epa 609 certification.