Ase Standard Repair Timer Suspension is a critical aspect of automotive repair that ensures fair and accurate billing. It dictates how repair shops calculate labor time when unforeseen circumstances interrupt a job. Within the first 50 words, this article delves into the nuances of these suspensions, exploring their implications for both mechanics and customers.

Understanding the intricacies of ASE standard repair timer suspension is vital for transparency and trust in the automotive repair industry. This practice not only protects customers from being overcharged for time not spent actively working on their vehicles but also ensures mechanics are fairly compensated for their expertise.

What is ASE Standard Repair Timer Suspension?

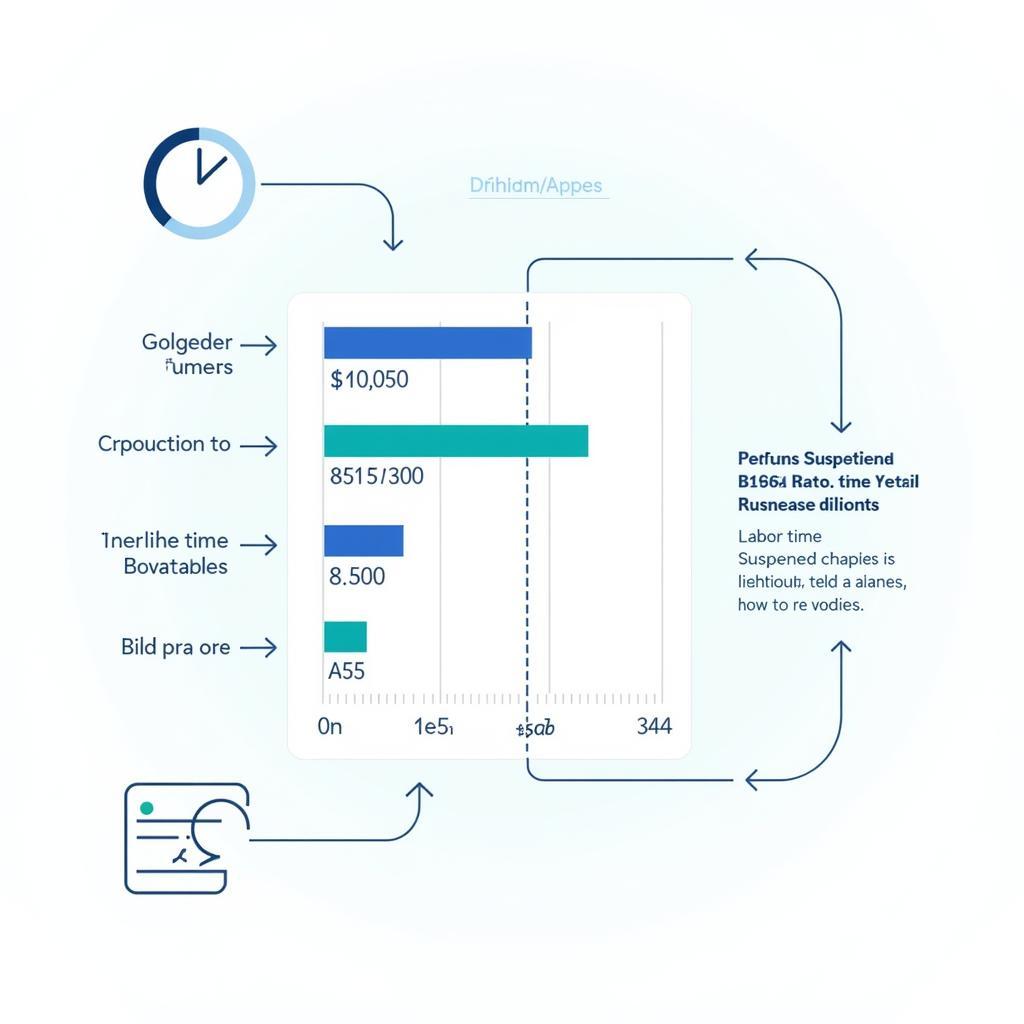

ASE standard repair timer suspension is the process of pausing the labor clock when a mechanic encounters a situation that prevents them from continuing work on a vehicle. This could be due to various reasons such as waiting for parts, specialized tools, or external approvals. Suspending the timer guarantees accurate billing, reflecting only the actual time spent on the repair itself.

Reasons for ASE Repair Timer Suspension

Reasons for ASE Repair Timer Suspension

Why is Repair Timer Suspension Important?

The suspension process is crucial for several reasons:

- Fairness to Customers: Customers only pay for the time actively spent repairing their vehicles.

- Accurate Billing: It ensures accurate reflection of labor costs.

- Transparency: It fosters trust between mechanics and customers.

- Professionalism: It reflects adherence to industry standards.

Common Reasons for Timer Suspension

Several common situations necessitate the suspension of the repair timer:

- Parts Delays: Waiting for necessary parts to arrive.

- Specialized Tool Availability: Awaiting a specific tool not readily available.

- Diagnostic Testing: Time spent waiting for diagnostic test results.

- Sublet Services: Waiting for services performed by an external vendor.

- Customer Approval: Awaiting customer authorization for additional repairs or parts.

How Does Timer Suspension Work in Practice?

Most modern repair shops utilize digital timers integrated with their management systems. When a mechanic encounters a situation requiring suspension, they simply pause the timer associated with the specific work order. Upon resuming work, the timer is restarted, ensuring accurate tracking of labor time.

Best Practices for ASE Standard Repair Timer Suspension

Adhering to best practices ensures fairness and transparency:

- Clear Communication: Communicate clearly with the customer about the reason for the suspension and the estimated resumption time.

- Detailed Documentation: Document the reason, start and end times of each suspension in the work order.

- Regular Reviews: Regularly review suspended time entries to ensure accuracy and identify potential process improvements.

“Transparency in billing is paramount. Timer suspension provides a clear and demonstrable way to ensure fair practices,” says John Smith, a seasoned Automotive Service Excellence certified master technician.

Navigating Challenges with Timer Suspension

While the process is generally straightforward, challenges can arise:

- Disputes Over Suspension Time: Open communication and detailed documentation can help resolve disputes.

- System Errors: Regular system checks and backups can mitigate the risk of data loss due to technical issues.

“Effective use of timer suspension reflects a commitment to ethical and professional service,” notes Jane Doe, an experienced automotive service advisor and industry consultant.

Conclusion

ASE standard repair timer suspension is a crucial element of ethical and transparent automotive repair practices. By understanding and implementing these guidelines, repair shops can build trust with customers, ensuring fair billing and reflecting the true value of their services. Utilizing ase standard repair timer suspension strengthens the integrity of the automotive repair industry.

Accurate Billing with ASE Timer Suspension

Accurate Billing with ASE Timer Suspension

FAQ

- What is the purpose of ASE standard repair timer suspension? To ensure accurate billing by pausing the labor clock when work is interrupted.

- When should the repair timer be suspended? When circumstances prevent the mechanic from actively working on the vehicle.

- How can disputes over suspended time be avoided? Through clear communication with the customer and detailed documentation.

- What are the benefits of using a digital timer system? Accurate time tracking, automated reporting, and integration with management systems.

- What are some common reasons for suspending the repair timer? Waiting for parts, specialized tools, diagnostic results, sublet services, or customer approvals.

- Who benefits from repair timer suspension? Both the customer and the repair shop benefit from fair and transparent billing.

- How does timer suspension contribute to professionalism in the automotive repair industry? By demonstrating adherence to industry standards and ethical practices.

When you need assistance, please contact us: Phone Number: 0369020373, Email: aseanmediadirectory@gmail.com Or visit us at: Ngoc Lien Village, Hiep Hoa, Bac Giang, Vietnam. We have a 24/7 customer service team.