ASE (Atomic Spectroscopy Emission) and Laser technology are two distinct analytical techniques used across various fields for elemental analysis and material characterization. While both offer valuable insights into the composition of a sample, they differ significantly in their working principles, applications, and strengths. This comprehensive guide delves into the intricacies of Ase Vs Laser, providing you with the knowledge to differentiate these techniques and select the most suitable one for your analytical needs.

Delving into Atomic Spectroscopy Emission (ASE)

ASE, also known as Optical Emission Spectrometry (OES), is a versatile technique employed to determine the elemental composition of a sample. This method relies on the principle of atomic emission, where atoms excited by an external energy source emit light at specific wavelengths unique to each element.

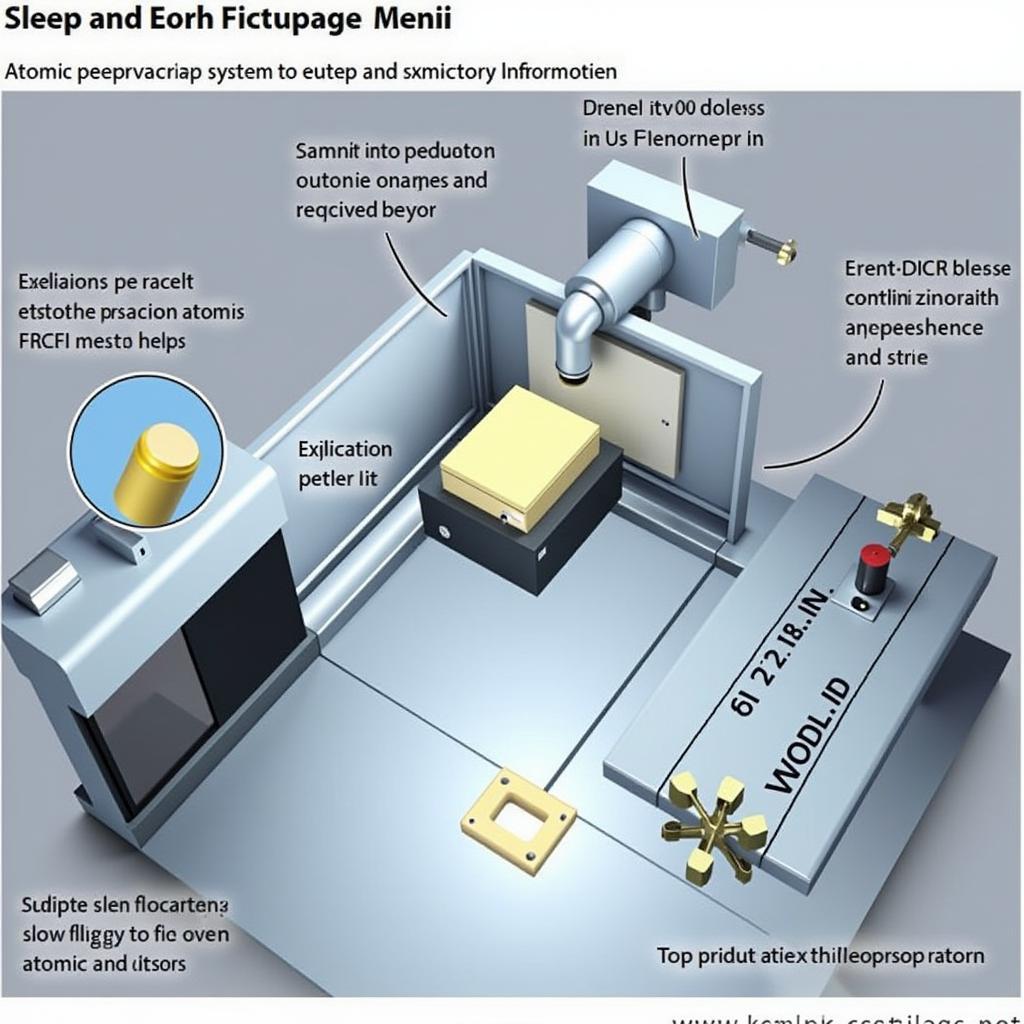

Atomic Spectroscopy Emission (ASE) Setup

Atomic Spectroscopy Emission (ASE) Setup

How ASE Works: A Step-by-Step Breakdown

- Sample Introduction: The process begins with introducing the sample, which can be in solid, liquid, or gas form, into the ASE instrument.

- Atomization and Excitation: The sample is then subjected to high temperatures, typically achieved through an inductively coupled plasma (ICP) or an arc/spark discharge. This high-energy environment causes the sample to atomize, breaking it down into its constituent atoms. Subsequently, these atoms get excited as they absorb energy.

- Light Emission: As the excited atoms return to their ground state, they release the absorbed energy in the form of light. This emitted light is characteristic of the element and its concentration in the sample.

- Wavelength Separation and Detection: The emitted light passes through a spectrometer, which separates it based on wavelength. A detector then measures the intensity of light at each specific wavelength, creating an emission spectrum.

- Quantitative Analysis: The intensity of the emitted light at a particular wavelength is directly proportional to the concentration of that element in the sample. By comparing the sample’s emission spectrum to those of known standards, the elemental composition and concentration can be accurately determined.

Advantages of ASE

- High Sensitivity: ASE stands out for its exceptional sensitivity, making it capable of detecting trace amounts of elements in a sample.

- Multi-element Capability: One of the significant advantages of ASE is its ability to analyze multiple elements simultaneously, saving time and resources.

- Versatility: ASE is highly versatile and can be used to analyze a wide range of sample types, including metals, minerals, environmental samples, and biological materials.

Exploring Laser Technology for Analysis

Laser technology, specifically Laser Ablation (LA) coupled with various detection techniques like Inductively Coupled Plasma Mass Spectrometry (ICP-MS), has revolutionized elemental analysis and material characterization. LA-ICP-MS combines the precision of laser ablation for sampling with the sensitivity and versatility of ICP-MS for elemental detection.

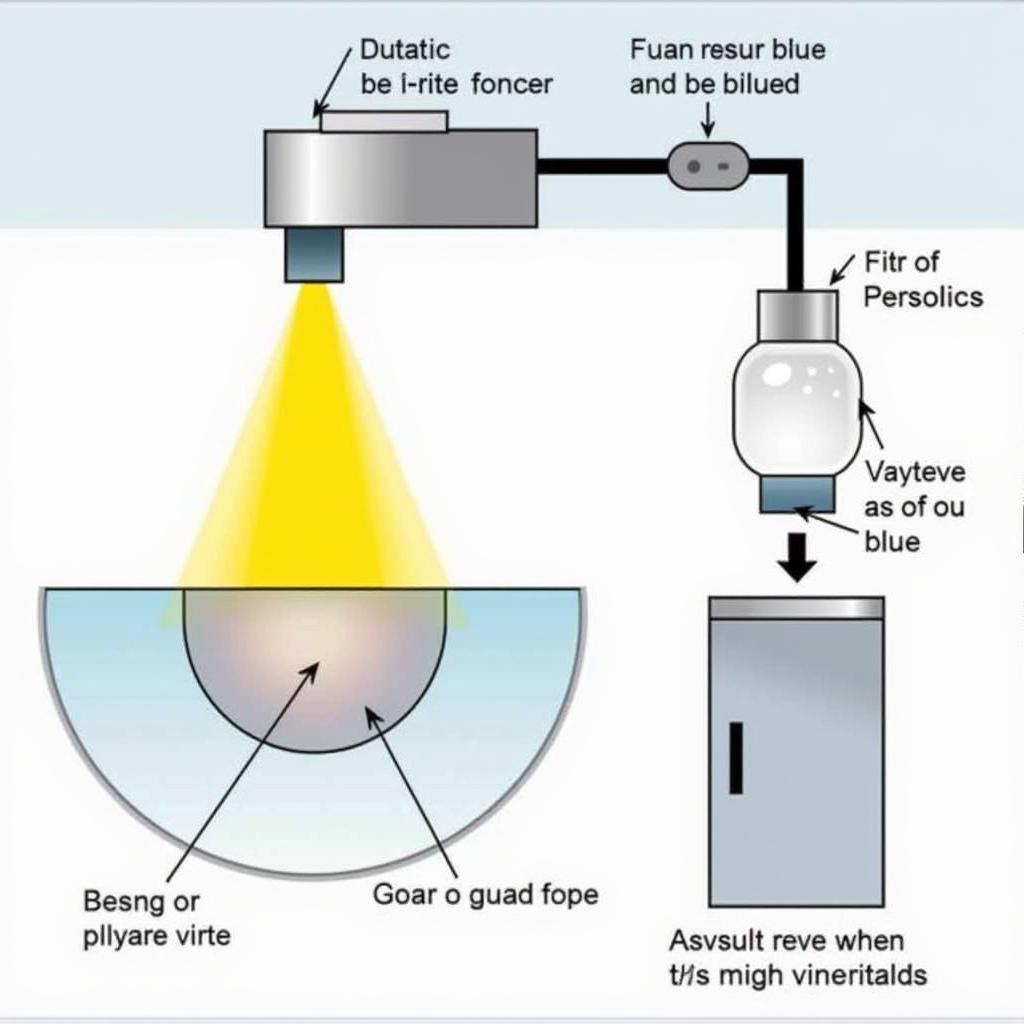

Laser Ablation Process in Material Analysis

Laser Ablation Process in Material Analysis

How Laser Ablation Works: A Closer Look

- Laser Focusing: A high-energy laser beam is focused onto the sample’s surface.

- Material Ablation: The intense energy of the laser beam interacts with the sample, causing rapid heating and vaporization of a small, well-defined area, leading to material ablation.

- Aerosol Generation: The ablated material forms a fine aerosol of particles.

- Elemental Analysis: This aerosol is then transported to an ICP-MS instrument, where the ablated material is further excited in the plasma. The ions generated are then separated based on their mass-to-charge ratio, allowing for the identification and quantification of different elements present in the sample.

Advantages of Laser Technology

- High Spatial Resolution: Laser ablation offers unparalleled spatial resolution, enabling the analysis of microscopic areas within a sample. This is particularly advantageous for studying heterogeneous materials or analyzing small features.

- Minimal Sample Preparation: LA-ICP-MS often requires minimal sample preparation, reducing the risk of contamination and making it a faster analytical technique compared to traditional methods.

- Depth Profiling: By controlling the laser parameters, depth profiling can be achieved, allowing for the analysis of elemental composition at different depths within the sample.

ASE vs Laser: Head-to-Head Comparison

| Feature | ASE | Laser (LA-ICP-MS) |

|---|---|---|

| Principle | Atomic emission spectrometry | Laser ablation followed by elemental detection |

| Sensitivity | High | Very high |

| Spatial Resolution | Low | High |

| Sample Type | Solid, liquid, gas | Mostly solid |

| Sample Preparation | Varies depending on the sample type | Minimal |

| Applications | Environmental monitoring, food chemistry, metallurgy | Geochemistry, materials science, archaeology |

| Cost | Lower | Higher |

Making the Right Choice: ASE or Laser?

Choosing between ASE and laser technology depends on the specific analytical requirements of your application.

Opt for ASE when:

- High sensitivity for trace element analysis is paramount.

- The sample is homogeneous, and bulk analysis is sufficient.

- A wide range of sample types needs to be analyzed.

Choose Laser technology when:

- High spatial resolution is critical, such as for analyzing microscopic features.

- Depth profiling or elemental mapping is required.

- Minimal sample preparation is preferred.

Conclusion

Both ASE and laser technology are powerful analytical tools offering unique advantages. By understanding their principles, strengths, and limitations, researchers and analysts can make informed decisions to select the most appropriate technique for their specific needs, ultimately advancing research and applications across diverse fields.

FAQs: ASE vs Laser

1. What types of samples are best suited for ASE analysis?

ASE is a versatile technique capable of analyzing various sample types, including:

- Environmental Samples: Water, soil, air, and plant matter

- Food and Beverages: Determining the elemental composition of food products

- Geological Materials: Minerals, rocks, and ores

- Biological Samples: Blood, urine, and tissue

- Metals and Alloys: Analyzing the composition of metals for quality control

2. What are the limitations of laser ablation for elemental analysis?

While laser ablation offers advantages like high spatial resolution, it has limitations:

- Matrix Effects: The ablation process can be influenced by the sample matrix, requiring careful calibration and matrix-matched standards for accurate quantification.

- Element Fractionation: Lighter elements might be preferentially ablated compared to heavier elements, potentially leading to biased results.

3. Can laser ablation be used for quantitative analysis?

Yes, laser ablation, when coupled with techniques like ICP-MS, can be used for quantitative analysis. However, achieving accurate quantification requires careful calibration and the use of appropriate standards.

4. What are some common applications of laser ablation in research?

Laser ablation finds applications in diverse research areas, including:

- Geochemistry: Analyzing the elemental composition of minerals and rocks

- Materials Science: Studying the composition and properties of advanced materials

- Archaeology: Dating artifacts and determining their provenance

- Art Conservation: Analyzing pigments and materials used in artworks

5. What factors should be considered when choosing between ASE and laser ablation for a specific application?

Several factors influence the choice between ASE and laser ablation:

- Analytical Sensitivity Required: ASE generally offers high sensitivity, while laser ablation coupled with ICP-MS can achieve even higher sensitivity.

- Spatial Resolution Needs: Laser ablation provides superior spatial resolution compared to ASE.

- Sample Characteristics: Sample type, size, and homogeneity play a crucial role in technique selection.

- Cost and Availability: ASE instruments are generally more affordable and widely available than laser ablation systems.

Need further assistance? Contact us at:

Phone: 0369020373

Email: aseanmediadirectory@gmail.com

Address: Thôn Ngọc Liễn, Hiệp Hòa, Bắc Giang, Việt Nam

Our dedicated customer support team is available 24/7 to answer your queries and provide comprehensive support.