The ASEAN region, known for its booming electronics industry, increasingly relies on advanced packaging technologies like the ASEAN WLCSP package. This miniaturized packaging solution has revolutionized electronics manufacturing, offering significant advantages in terms of size, performance, and cost-effectiveness.

WLCSP Package Dimensions

WLCSP Package Dimensions

What is an ASEAN WLCSP Package?

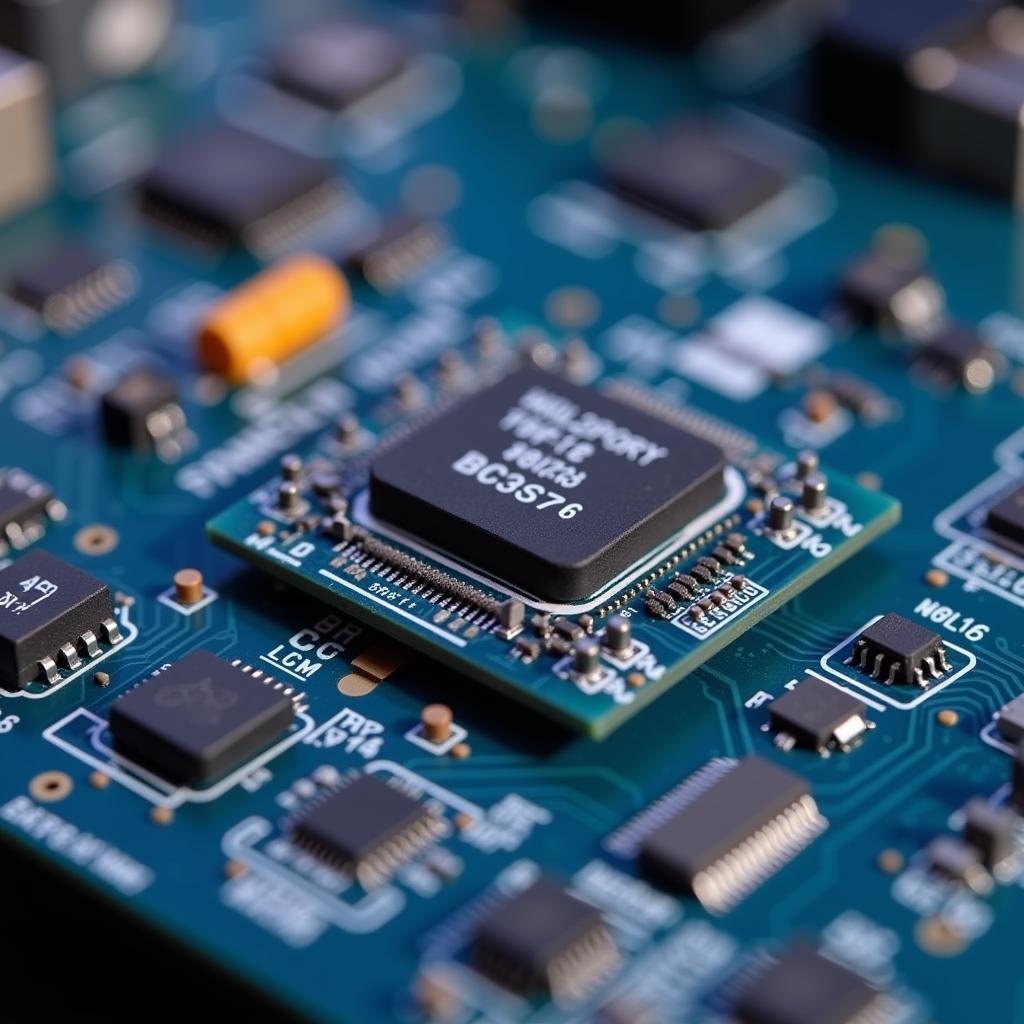

WLCSP stands for Wafer Level Chip Scale Package, a form of integrated circuit packaging that’s directly mounted and ball grid array (BGA) packaged on the wafer, eliminating the need for a separate package substrate. This unique approach allows the package size to be almost equivalent to the die size, making it ideal for applications where miniaturization is paramount.

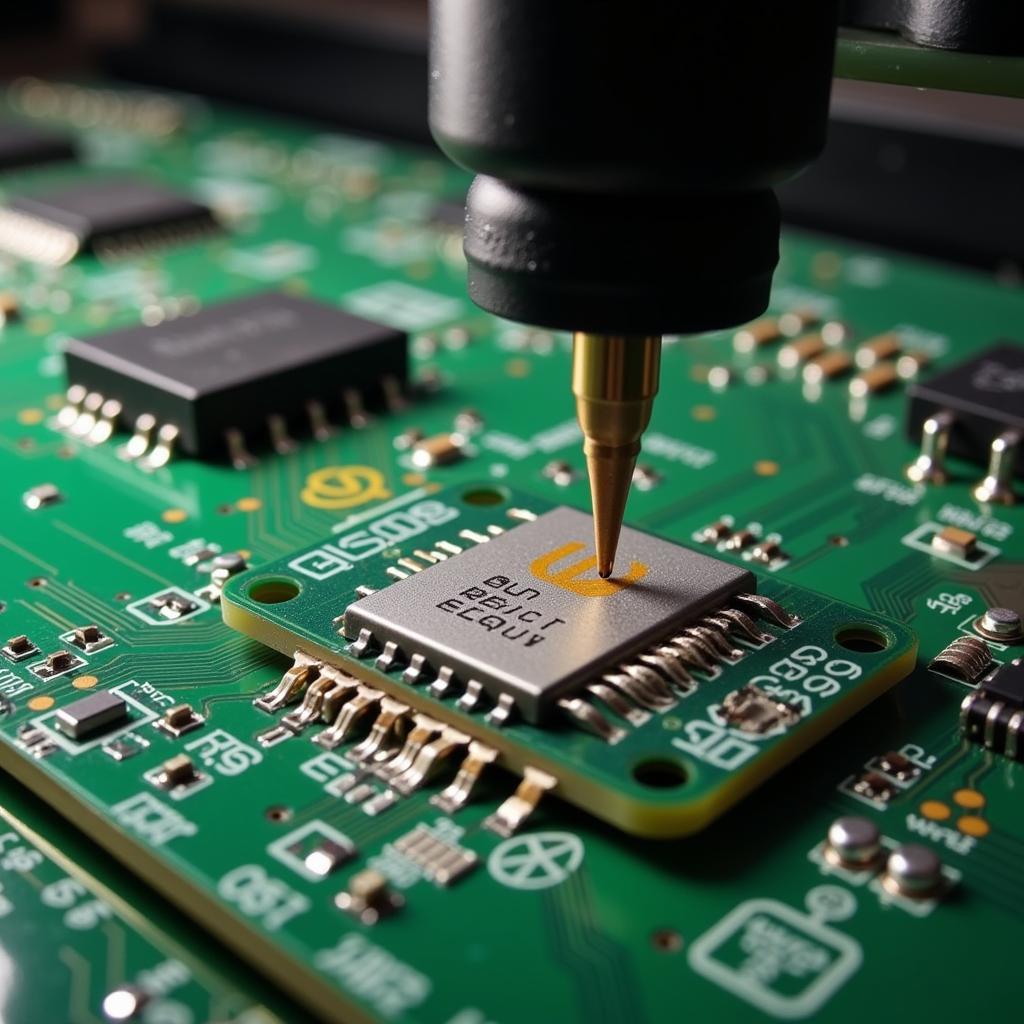

WLCSP Package Mounted on PCB

WLCSP Package Mounted on PCB

Benefits of Choosing WLCSP in ASEAN

The adoption of WLCSP technology offers numerous benefits, making it a preferred choice for manufacturers in the ASEAN region and beyond. Some key advantages include:

- Ultra-Small Form Factor: WLCSP packages are exceptionally compact, enabling the development of smaller and lighter electronic devices without compromising on functionality.

- Enhanced Electrical Performance: The direct connection between the die and PCB minimizes parasitic inductance and capacitance, leading to improved signal integrity and faster data transfer rates.

- Excellent Thermal Dissipation: The reduced size and direct die attachment enhance heat dissipation, leading to lower operating temperatures and improved device reliability.

- Cost-Effective Solution: WLCSP packaging simplifies the manufacturing process and reduces material usage, resulting in cost savings for manufacturers.

Applications of ASEAN WLCSP Packages

The versatility of WLCSP packaging has led to its widespread adoption across various industries in the ASEAN region:

- Mobile Devices: Smartphones, tablets, and wearable devices benefit from the small size and high performance offered by WLCSP packages.

- Consumer Electronics: From digital cameras to audio devices, WLCSPs enable the creation of sleek and feature-rich electronics.

- Automotive Industry: WLCSP packages play a vital role in advanced driver-assistance systems (ADAS), infotainment systems, and other automotive electronics.

- Medical Devices: The compact size and reliability of WLCSPs make them suitable for use in hearing aids, pacemakers, and other medical implants.

The Future of WLCSP in ASEAN

The demand for smaller, faster, and more powerful electronics is continuously rising, and WLCSP technology is well-positioned to meet these evolving demands. As the ASEAN electronics industry continues to flourish, the adoption of WLCSP packages is expected to witness significant growth. This trend is further driven by the increasing focus on miniaturization, improved performance, and cost optimization across various sectors.

Conclusion

The ASEAN WLCSP package stands as a testament to the region’s commitment to innovation in the electronics industry. Its unparalleled ability to combine miniaturization with enhanced performance and cost-effectiveness makes it a game-changer in the world of electronics manufacturing. As technology continues to advance, WLCSP is expected to play an increasingly pivotal role in shaping the future of electronics in ASEAN and beyond.

FAQs about ASEAN WLCSP Package

1. What are the key differences between WLCSP and other packaging technologies?

WLCSP differentiates itself by packaging the die directly onto the wafer, resulting in a significantly smaller footprint compared to traditional packaging methods. This direct connection also offers performance advantages such as improved electrical conductivity and thermal management.

2. What are the typical applications of WLCSP packages in the ASEAN region?

WLCSP packages are widely used in mobile devices, consumer electronics, automotive electronics, and medical devices within ASEAN. Their small size, enhanced performance, and cost-effectiveness make them suitable for a diverse range of applications.

3. How does the cost of WLCSP packaging compare to other options?

While the initial wafer processing for WLCSP can be slightly more expensive, the overall cost is often lower due to the simplified assembly process, reduced material usage, and higher production yields.

4. What are the future trends in WLCSP technology?

The future of WLCSP is expected to be driven by further miniaturization, integration of new materials, and development of advanced packaging techniques to accommodate increasing transistor densities and performance demands.

5. Where can I get more information about ASEAN WLCSP packaging?

For further assistance and information, please contact us at:

Phone Number: 0369020373

Email: [email protected]

Address: Thon Ngoc Lien, Hiep Hoa, Bac Giang, Vietnam

Our dedicated customer support team is available 24/7 to assist you.