Asea Bushings Gob 250 O-rings play a crucial role in ensuring the safety and reliability of electrical equipment. These components are essential for sealing and protecting the bushings from environmental factors and ensuring optimal performance. This article will delve into the specifics of ASEA bushings GOB 250 O-rings, exploring their function, materials, installation, maintenance, and troubleshooting.

Understanding the Role of ASEA Bushings GOB 250 O-Rings

Bushings are vital components in electrical systems, enabling the passage of conductors through grounded barriers like transformer tanks or switchgear enclosures. The GOB 250 designation refers to a specific type of ASEA bushing. The O-ring within this system provides a critical seal, preventing moisture, dust, and other contaminants from entering the bushing and compromising its integrity. This protection helps maintain the dielectric strength of the bushing and prevents potential failures that could lead to costly downtime and safety hazards. Properly functioning O-rings are essential for the long-term reliability of the bushing and the overall electrical system.

Choosing the correct O-ring material is critical for ensuring its compatibility with the bushing’s operating environment. Common materials include nitrile (NBR), silicone (VMQ), and ethylene propylene diene monomer (EPDM) rubber. Each material has its own strengths and weaknesses, with varying resistance to chemicals, temperature extremes, and mechanical wear.

Installing and Maintaining ASEA Bushings GOB 250 O-Rings

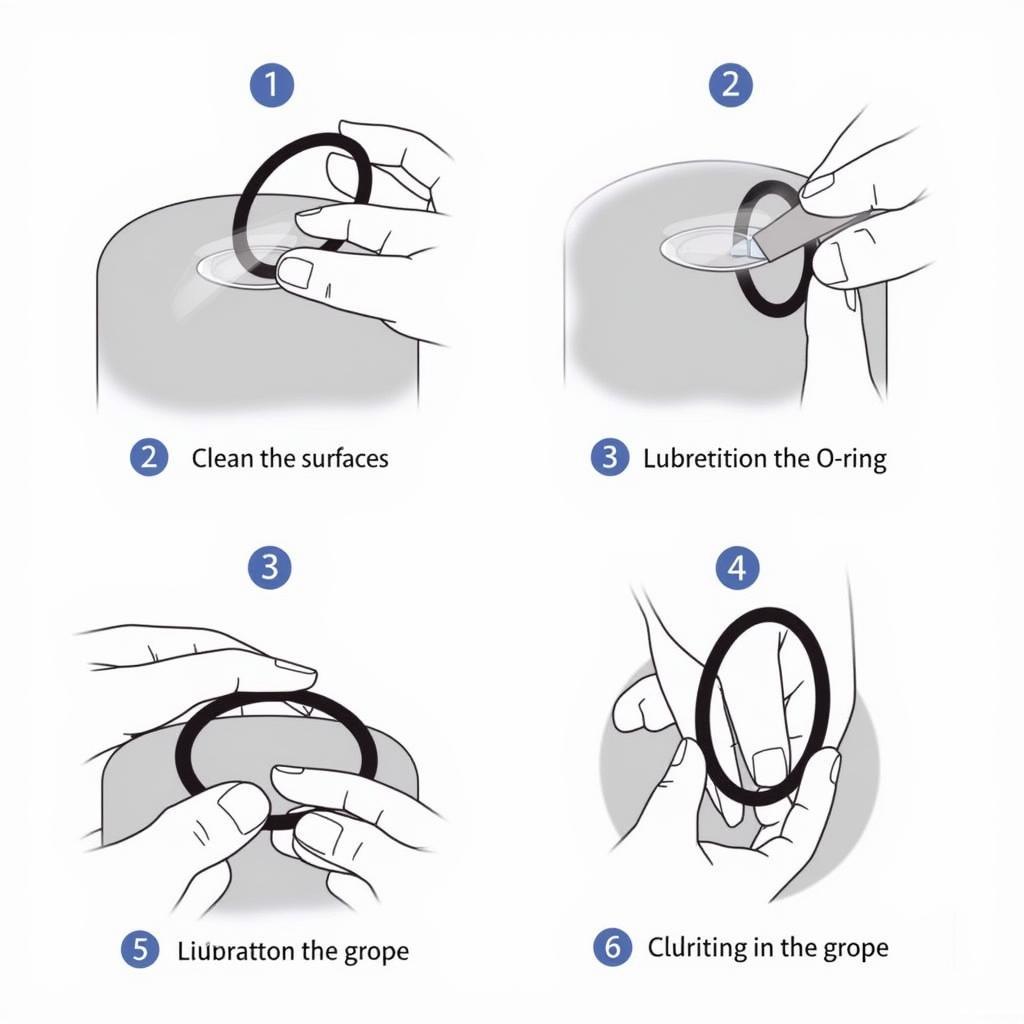

Proper installation is crucial for the effective sealing performance of ASEA bushings GOB 250 O-rings. Before installation, ensure the bushing and surrounding surfaces are clean and free from debris. Lubricate the O-ring with a compatible lubricant to prevent damage during installation and ensure a proper seal. Carefully position the O-ring in its designated groove, avoiding twisting or stretching. Over-tightening during installation can also damage the O-ring, so follow the manufacturer’s recommended torque specifications.

Regular inspection and maintenance are essential for extending the lifespan of ASEA bushings GOB 250 O-rings. Inspect the O-rings for signs of wear, cracking, or deformation during routine maintenance checks. Replace any damaged O-rings immediately to prevent potential leaks and failures. Keep detailed records of maintenance activities, including the date of replacement and the type of O-ring used.

ASEA Bushing GOB 250 O-Ring Installation Process

ASEA Bushing GOB 250 O-Ring Installation Process

Troubleshooting Common Issues with ASEA Bushings GOB 250 O-Rings

Leaks are the most common problem associated with faulty O-rings. If a leak is detected, inspect the O-ring for damage and replace it if necessary. Ensure the O-ring is properly seated in its groove and that the bushing is correctly installed. Persistent leaks may indicate a more serious problem with the bushing itself.

Another common issue is O-ring degradation due to chemical exposure or extreme temperatures. If the O-ring appears brittle, cracked, or swollen, it should be replaced with a material more suitable for the operating environment.

“Choosing the right O-ring material for your specific application is paramount,” says Thomas Nguyen, Senior Electrical Engineer at Power Grid Solutions. “Using the wrong material can lead to premature failure and costly repairs.”

Conclusion: Ensuring the Longevity of Your ASEA Bushings GOB 250 O-Rings

Proper selection, installation, and maintenance of ASEA bushings GOB 250 O-rings are critical for the safety and reliability of your electrical equipment. Regular inspections, timely replacements, and choosing the correct O-ring material will help prevent costly downtime and ensure the long-term performance of your bushings. Remember that investing in high-quality O-rings and adhering to proper maintenance practices is a crucial aspect of maintaining a reliable and efficient electrical system.

“Preventive maintenance is key to avoiding costly repairs down the line,” adds Maria Santos, a seasoned Maintenance Technician with over 20 years of experience. “Regularly checking and replacing your O-rings can save you significant time and money.”

FAQ

- What is the function of an O-ring in an ASEA bushing? To create a seal, preventing contaminants from entering.

- What are the common materials used for ASEA bushing GOB 250 O-rings? NBR, Silicone, and EPDM rubber.

- How often should I inspect my ASEA bushing GOB 250 O-rings? During routine maintenance checks, typically every six months.

- What should I do if I detect a leak around the O-ring? Inspect the O-ring and replace it if necessary.

- What are the signs of a degraded O-ring? Brittleness, cracking, or swelling.

- How can I ensure the proper installation of an ASEA bushing GOB 250 O-ring? Clean surfaces, proper lubrication, and correct positioning.

- What are the consequences of using the wrong O-ring material? Premature failure and costly repairs.

For further assistance, please contact us at Phone Number: 0369020373, Email: aseanmediadirectory@gmail.com or visit us at Thôn Ngọc Liễn, Hiệp Hòa, Bắc Giang, Việt Nam. We have a 24/7 customer support team.