Asea Geared Motors play a crucial role in various industries across Southeast Asia, providing reliable and efficient power transmission solutions. From manufacturing and processing to mining and construction, these motors are essential for driving a wide range of equipment and machinery. Understanding their importance and selecting the right ASEA geared motor can significantly impact operational efficiency and productivity.

Understanding the Importance of ASEA Geared Motors

ASEA geared motors are specifically designed to deliver high torque at lower speeds, making them ideal for applications requiring precise control and consistent power output. Their robust construction and adaptability make them suitable for harsh operating environments often encountered in Southeast Asian industries. Choosing the right ASEA geared motor ensures optimal performance, reduces downtime, and contributes to long-term cost savings.

What are the key benefits of using ASEA geared motors? They offer improved efficiency, reduced energy consumption, enhanced operational lifespan, and precise speed control. Furthermore, these motors are highly adaptable to various industrial applications, offering versatility and reliability.

Selecting the Right ASEA Geared Motor for Your Needs

Choosing the correct ASEA geared motor requires careful consideration of several factors, including the specific application, required torque and speed, operating environment, and budget. Understanding these parameters ensures the selected motor meets the demands of the application and delivers optimal performance. What factors should you consider when selecting an ASEA geared motor? Key considerations include:

- Power Requirements: Determine the necessary horsepower or kilowatt rating.

- Speed and Torque: Evaluate the required output speed and torque for the application.

- Duty Cycle: Assess the motor’s operating time and frequency of starts and stops.

- Environmental Conditions: Consider factors like temperature, humidity, and exposure to dust or chemicals.

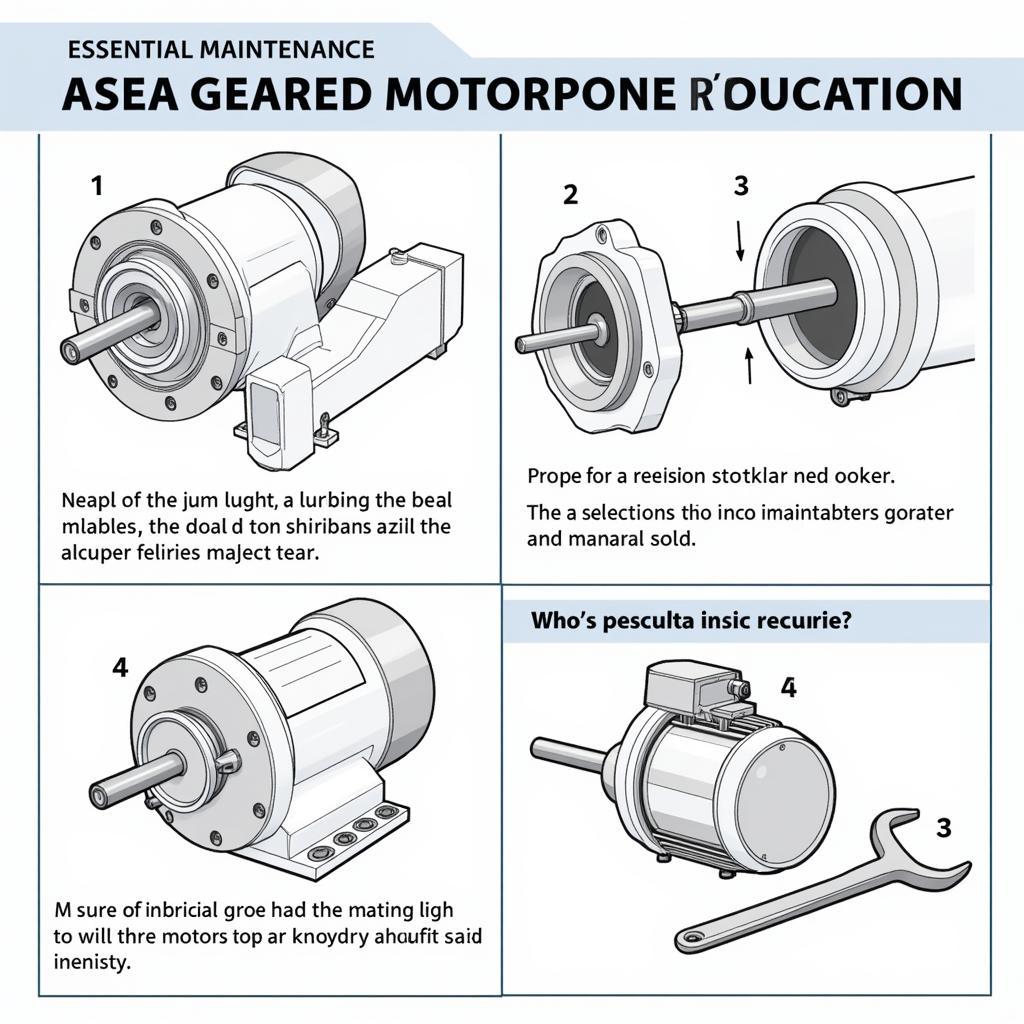

Maintenance and Troubleshooting of ASEA Geared Motors

Regular maintenance is crucial for ensuring the longevity and optimal performance of ASEA geared motors. Proper lubrication, inspection for wear and tear, and timely repairs can prevent costly downtime and extend the motor’s lifespan. How can you maintain your ASEA geared motor effectively? Key maintenance practices include:

- Regular lubrication with the correct type and grade of lubricant.

- Periodic inspections for signs of wear and tear, such as noise, vibration, or overheating.

- Promptly addressing any issues to prevent further damage.

- Following the manufacturer’s recommended maintenance schedule.

“Regular maintenance is the key to maximizing the lifespan and performance of your ASEA geared motors,” advises Mr. Rajeev Kumar, a senior mechanical engineer with extensive experience in industrial automation in Southeast Asia. “Neglecting maintenance can lead to premature failures and costly repairs.”

ASEA Geared Motor Maintenance Procedures

ASEA Geared Motor Maintenance Procedures

The Future of ASEA Geared Motors in Southeast Asia

ASEA geared motors are poised to play an even more significant role in the future of Southeast Asian industries. As the region continues to experience rapid industrialization and technological advancements, the demand for efficient and reliable power transmission solutions will only increase. “The future of industrial automation in Southeast Asia relies heavily on robust and adaptable technologies like ASEA geared motors,” notes Ms. Anya Sharma, a leading consultant in industrial automation across the ASEAN region.

Conclusion

ASEA geared motors are essential components in various industries across Southeast Asia, providing reliable power transmission solutions for a wide range of applications. Selecting the right motor and implementing a proper maintenance schedule are crucial for ensuring optimal performance and longevity. Investing in high-quality ASEA geared motors is an investment in the future of your operations.

FAQ

- What are the main applications of ASEA geared motors in Southeast Asia?

- How do I choose the right ASEA geared motor for my specific needs?

- What are the key maintenance practices for ASEA geared motors?

- Where can I find reliable suppliers of ASEA geared motors in Southeast Asia?

- What are the typical lifespan and warranty periods for ASEA geared motors?

- How do ASEA geared motors compare to other types of geared motors in terms of performance and efficiency?

- What are the latest technological advancements in ASEA geared motors?

Commonly Asked Questions

- Problem: My ASEA geared motor is making unusual noises. Solution: This could indicate a lubrication issue or worn-out bearings. Consult a qualified technician for inspection and repair.

- Problem: The motor is overheating. Solution: Overheating can be caused by overloading, inadequate ventilation, or electrical issues. Check the load, ensure proper ventilation, and consult a technician if the problem persists.

Further Exploration

- Explore more articles on industrial automation in Southeast Asia on our website.

- Learn more about different types of geared motors and their applications.

Need assistance with ASEA geared motors? Contact us at Phone Number: 0369020373, Email: aseanmediadirectory@gmail.com or visit us at Thôn Ngọc Liễn, Hiệp Hòa, Bắc Giang, Việt Nam. We have a 24/7 customer support team ready to assist you.